The vital facilitator for sustainable global progress lies in the accessibility of economical, dependable, and eco-friendly energy. As countries undergo swift transformations, the requirement for abundant energy sources becomes imperative to sustain their developmental momentum. With a burgeoning population, rapid urbanization, increasing incomes, and elevated living standards, India has ascended to become the world’s third-largest energy consumer, as per the findings of the International Energy Agency.

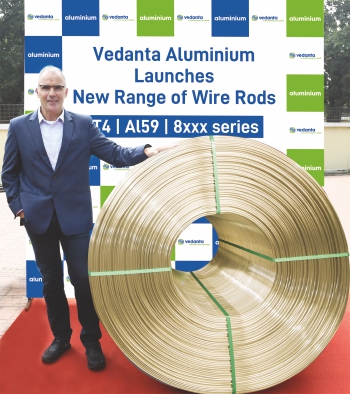

India’s ambitious goal to reach Net Zero carbon emissions by 2070, combined with the objective of fulfilling 50 percent of its electricity demands through renewable energy sources by 2030, anticipates a transformative era in the energy sector. Aluminium, a metal that has extensive applications in the space of power generation, distribution, and storage, is playing a significant role as an enabler of this revolution. With clean energy increasingly pivotal to the country’s aspirations, the domestic aluminium industry will have a crucial role to play, and Vedanta Aluminium, India’s largest producer of aluminium, is well-resourced to cater to this journey. Towards this goal, the company is consistently expanding its product portfolio by redefining excellence in product offerings for the global power and transmission sector. Recently, the company launched a new range of advanced wire rods, namely T4, AL59, and the 8xxx series that find key applications in automotive, building, infrastructure, and electronics apart from the power and transmission sector.

Mr. John Slaven, Chief Executive Officer of Vedanta Aluminium, states “Aluminium is emerging as a key raw material in the electrical sector to advance worldwide access to clean and dependable energy, expediting the journey towards sustainability. At Vedanta Aluminium, we continually enhance our product portfolio to cater to the changing dynamics of the sector. We are committed to partnering with our customers to provide tailored, premium solutions for all their requirements. Our new range of specialized alloy wire rods is another step towards offering our customers high-quality products to serve their evolving needs. We aim not only to drive manufacturing excellence for our customers but also help them achieve their net zero goals.”

Powering Up with Aluminium

The versatility of aluminium is widely known, as is its ability to expand its applications in conjunction with materials such as magnesium, copper, and silicon. High structural strength, lightweight, excellent conductivity, high ductility, and non-magnetic properties have made aluminium and its several alloys indispensable for the electrical industry. The major areas of applications within this sector include cables, busbars, overhead transmission lines, motors, foil windings, electrolytic capacitors, heating elements, heat sinks, and many more.

Aluminium offers exceptional design flexibility as well as superb conductivity. Among base metals, only copper has a higher conductivity than aluminium. However, aluminium is twice as light and durable in the face of weather elements, and much more cost-effective, which makes aluminium wire rods the preferred choice for deploying extensive networks of power transmission lines.

Weight is a crucial parameter for high-voltage power lines that transmit electricity over long distances. Aluminium wires reduce the load on grid pylons and increase the distance between them, reducing expenses and shortening construction time.

The lightweight nature of aluminium wire rods makes them highly effective in preventing the sagging of transmission lines, a critical factor in ensuring efficient power distribution across long distances. This is further bolstered by the fact that aluminium has good ductility and formability and sustains significant static loads.

Another special property of aluminium is that it is non-corrosive, ensuring a significantly longer service life (almost 40 years) with minimal maintenance. So, on a cost-benefit analysis, aluminium ranks significantly higher than traditional metals. Furthermore, at the end of its usage life, aluminium can be 100 percent recycled with barely any loss in properties. This is an especially big plus in India’s quest for a circular economy, ensuring that its resources are gainfully utilized.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

Vedanta Aluminium – Energising India

With an installed production capacity of 2.3 million tonnes per annum, Vedanta Aluminium’s operations include one of the world’s largest aluminium smelting facilities at Jharsuguda Odisha, along with BALCO which is India’s iconic aluminium producer based in Korba, Chhattisgarh. With a production capacity of 650-kilo tonnes in wire rod production, Vedanta Aluminium offers top-quality electrical conductor (EC) grade wire rods with diameters available in the range of 7.6mm, 9.5mm, 12mm, and 15mm, as well as alloy wire rods and flip coils, produced using best-in-class technologies from Southwire (USA) and Continnus-Properzi (Italy). Given such scale and range of production, the company has also emerged as the largest producer of wire rods globally (ex-China).

The newly unveiled T4 alloy wire rods offer customers the advantages of low-sag high strength, high drawability, and enhanced durability. These properties make it perfect for usage within high-voltage transmission grids and also in manufacturing optical fiber composite overhead wires. In addition, the AL59 alloy rods offer a higher strength-to-weight ratio, superior power evacuation, and a significantly higher current carrying capacity. These attributes are essential to produce durable cables and conductors. Furthermore, the 8xxx series of wire rods offer exceptional anti-corrosion properties, making it immensely valuable for the construction, transportation, and architectural sectors, which need a perfect balance of malleability and durability.

With purity levels as high as 99.99 percent and extended durability, the company also offers product solutions for specialized applications such as submarine cables, transformer windings, and HVAC (Heating, Ventilation, and Air Conditioning) systems.

Beyond its product offerings that meet the specific needs of the wire and cable industry, Vedanta Aluminium caters to sectors such as automotive, building & construction, infrastructure, aerospace, aviation, consumer goods, packaging, and many others. In addition to wire rods, the company also produces one of the largest ranges of high-quality aluminium products in the global industry, including Restora (low-carbon, ‘green’ aluminium), Billets, Primary Foundry Alloy (PFA), Slabs, Ingots, Rolled Products, Flip Coils, and hot/liquid metal.

Vedanta Aluminium’s broad product range bears the Bureau of Indian Standards (BIS) certification, underscoring its exceptional quality. The company’s products have also been verified as environmentally sustainable by the globally recognized Environmental Product Declaration (EPD), after undergoing a rigorous Life Cycle Assessment (LCA), performing well on the parameters of energy consumption, greenhouse gas emissions, water usage, and waste generation. Additionally, the Aluminium Stewardship Initiative (ASI), has also certified the company’s plant at Jharsuguda, Odisha for showcasing high sustainability performance, a coveted indicator of sustainability worldwide.

Sustainable Products to Decarbonise the Value Chain

Vedanta Aluminium takes the lead in India by providing eco-friendly, low-carbon aluminium known as Restora and Restora Ultra to its worldwide clientele. Many of these clients are dedicated to making environmentally conscious choices in every aspect of their operations. They place a high importance on the sustainability of their materials procurement process and are committed to reducing carbon emissions across every stage of their value chain.

Under the brand Restora, the company offers two product lines – Restora (low-carbon aluminium) and Restora Ultra (ultra-low-carbon aluminium). Manufactured using renewable energy, Restora has a greenhouse gas (GHG) emission intensity that is at about 4 tonnes of CO2 equivalent per ton of aluminium manufactured. 4 tonnes of CO2 per ton of aluminium produced is the global threshold for aluminium to be considered as low carbon footprint aluminium. Restora Ultra, made with aluminium recovered from dross (a by-product of aluminium smelting), has an even lower carbon footprint that is near zero which is amongst the lowest in the world. It is a testament to the company’s focus on ‘zero-waste’ through streamlined operational efficiencies.

Also Read: HFCL Focuses on Exports on Back of its Diverse Offerings, Capacity Expansion and Strong R&D Investments

“Restora has a greenhouse gas (GHG) emission intensity that is at about 4 tonnes of CO2 equivalent per ton of aluminium manufactured, the global threshold for aluminium to be considered as low carbon footprint aluminium.”

Partnership for Success

Customer obsession is at the heart of Vedanta Aluminium’s product design and innovation. This has seen the company focus on developing customized solutions for both mass deployment and niche applications. For instance, it is developing application-centric customizations of wire rods for the power industry, such as for power transmission in coastal belts, which have specific requirements due to their climatic conditions. With its engineering prowess, deep R&D capabilities, vibrant Innovation Cell, Centre of Quality Excellence, and Customer Technical Service (CTS) function, the company is well-resourced to meet the needs of its global customer base, which spans nearly 50+ countries at present.

The company has also established one of India’s largest Aluminium Parks in close proximity to its operations at Jharsuguda, Odisha, home to one of the world’s largest aluminium smelters. This state-of-the-art Park is designed to cater to the needs of downstream producers, offering them the benefits of increased productivity, reduced turnaround times, and lower working capital requirements. Proximity to the Aluminium Park will also provide customers with access to Vedanta’s R&D and innovation facilities, and an extensive network of global experts. With a strategic geographic location and features that offer unparalleled advantages, the Vedanta Aluminium Park is set to attract aluminium-based SMEs and original equipment manufacturers (OEMs) specializing in various sectors like electrical, cables & conductors, extrusion, casting, auto ancillaries, and packaging.

“According to leading research firms, the global aluminium wire market is projected to reach USD 69.7 Billion by 2031, growing at a CAGR of 3.3 percent from 2022 to 2031.”

Robust Outlook

According to leading research firms, the global aluminium wire market is projected to reach USD 69.7 Billion by 2031, growing at a CAGR of 3.3 percent from 2022 to 2031. In India alone, energy consumption levels have almost doubled since the year 2000, and the potential for further growth remains enormous. The future of its electricals market is especially bright with growth in the industry driven by the recent developmental push in the power and infrastructure segments and conducive government policies. The wires & cables sector is a direct beneficiary of the power generation and distribution infrastructure.

Through its consistent research and development, global industry partnerships, and customized product offerings backed by top-notch customer service, Vedanta Aluminium has established itself as a trusted and reliable source of high-quality products at large volumes. With power needs expected to surge in coming years, the four ever-dynamic pillars of economy, population, urbanization, and industrialization will continue to keep Vedanta Aluminium busy at the heart of India’s energy and electrical ecosystem.