The double-shielding design of the cable makes it suitable for robotic applications with continuous torsion loads.

March 26, 2019

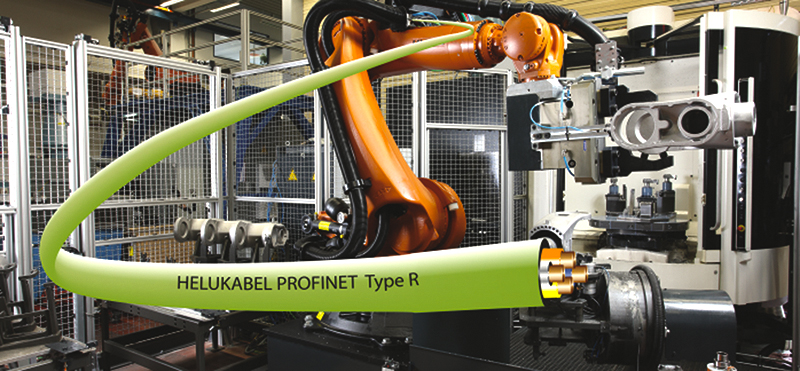

HELUKABEL, one of the leading global manufacturers and suppliers of cable, wires, and accessories, has added a new PROFINET cable to its broad portfolio of industrial ethernet cables — HELUKAT PROFINET type-r torsion.

As technology has changed to more automated equipment in industrial applications, customers are shifting from using systems that use PROFIBUS protocol to ones that use PROFINET because of the increased data-transmission rates required to maintain operational efficiency in real-time.

Dynamic requirements like acceleration and speed have increased and created more mechanical stress and electromagnetic interference (EMI). Increased EMI is a byproduct of robot density — i.e., more robots in the same production cell — and the higher speeds, because in order to produce the required acceleration, the motors need more power/torque.

HELUKAT PROFINET type-r torsion is rated Category 5e and offers excellent transmission characteristics in EMI-heavy environments due to its double-shielding design that is suited for robotic applications that undergo continuous torsion loads. It has been tested to withstand more than 5 million torsion cycles under loads of +/-180O/m, and more than 5 million flexing cycles in a drag chain at acceleration rates of two Gs (20 m/s2) and a maximum speed of 11 mph (300 m/min).

It can be used in environments that vary in temperature between -40OF and +176OF (-40OC – +80OC). The PUR jacket is flame-retardant and halogen-free according to IEC 60332-1-2 and 60754-1, respectively. Additionally, the HELUKAT PROFINET Type R Torsion is UL recognized under AWM Style 21161 80OC and meets the standards according to ISO/IEC 11801 and EN 50173.