wire trade fair will take place in Düsseldorf from April 16th to 20th, 2018. Wire & Cable India presents a preview of wire and cable manufacturing related companies and what all they are going to exhibit at the show. At the fair, visitors will find companies related wire manufacturing and finishing machinery; process technology tool; auxiliary process technology materials; materials, special wires and cables; glass fiber; measuring and control technology; test engineering; and other specialist areas.

Rosendahl Nextrom

The wire Dusseldorf 2018 and Rosendahl Nextrom

Industry 4.0 is breaking ground in the cable business. Not only does Rosendahl as suppliers think about how it can support its customers in being smart, it has also implemented smart tools in its factory to make facilities more efficient and innovative.

Preparations are already in full swing. For Rosendahl Nextrom, it is the largest and most important trade fair in the cable market. The company will be exhibiting in Düsseldorf with a 357 m² stand and a large team of Rosendahl Nextrom. It has changed the concept of the stand too, which now offers lots of nice surprises. The goal is to inform and entertain the visitors throughout the week. Here is a small overview of what you can expect to see during Wire 2018. Smart with Rosendahl Nextrom If Rosendahl looks back on what has happened since 2016, it sees that it has arrived at a new level of technology. Industry 4.0 is breaking ground in the cable business. Not only does Rosendahl as suppliers think about how it can support its customers in being smart, it has also implemented smart tools in its factory to make facilities more efficient and innovative. At Wire 2018, visitors see what has changed and what Rosendahl can do for wire and cable company’s success. Rosendahl has prepared many highlights for the visitors, such as our Smart Line Control System RIO and technologies for silicone extrusion and fiber optic cable production. It will present some preform samples made at its Preform R&D Technology Center. Moreover, it will take along a nice set of smart service packages that help companies to keep their system running smoothly. These are just a few items, though. Rosendahl is heading towards an even higher level of customization. So, wire Dusseldorf 2018 is just around the corner. Rosendahl has fully committed itself to making it an unforgettable show for mind, body and soul. Visitors may visit Rosendahl at booth #A60 in hall 9.

Preparations are already in full swing. For Rosendahl Nextrom, it is the largest and most important trade fair in the cable market. The company will be exhibiting in Düsseldorf with a 357 m² stand and a large team of Rosendahl Nextrom. It has changed the concept of the stand too, which now offers lots of nice surprises. The goal is to inform and entertain the visitors throughout the week. Here is a small overview of what you can expect to see during Wire 2018. Smart with Rosendahl Nextrom If Rosendahl looks back on what has happened since 2016, it sees that it has arrived at a new level of technology. Industry 4.0 is breaking ground in the cable business. Not only does Rosendahl as suppliers think about how it can support its customers in being smart, it has also implemented smart tools in its factory to make facilities more efficient and innovative. At Wire 2018, visitors see what has changed and what Rosendahl can do for wire and cable company’s success. Rosendahl has prepared many highlights for the visitors, such as our Smart Line Control System RIO and technologies for silicone extrusion and fiber optic cable production. It will present some preform samples made at its Preform R&D Technology Center. Moreover, it will take along a nice set of smart service packages that help companies to keep their system running smoothly. These are just a few items, though. Rosendahl is heading towards an even higher level of customization. So, wire Dusseldorf 2018 is just around the corner. Rosendahl has fully committed itself to making it an unforgettable show for mind, body and soul. Visitors may visit Rosendahl at booth #A60 in hall 9.

(Booth A60; Hall 9)

SIKORA AG

“The wire and cable business is one of our core markets.”

—Harry Prunk,

Executive board SIKORA AG

Wire 2018, from 16th to 20th April 2018, is with 70,000 visitors the largest trade exhibition for wire and cable and known in the industry as the leading trade fair for the international market. Again this year, SIKORA will be present with a booth. In our interview with Harry Prunk, we asked about the importance of the trade fair for SIKORA, the possibilities of measuring technologies in terms of Industry 4.0 and about the technical highlights that will be presented by SIKORA.

Wire & Cable India: Mr. Prunk, the ‘wire’ is one of the oldest leading trade fairs for wire and cable. How important is this exhibition to SIKORA?

Harry Prunk: Every other year, all stakeholders of the wire and cable industry meet in Düsseldorf. Manufacturers, processors, suppliers and providers use this week to discuss technologies, projects and trends of the industry. SIKORA has been participating in the exhibition since 1976, and still today, the wire and cable business is one of our core markets. Therefore, the ‘wire’ is for us the most important trade fair for the wire and cable industry worldwide. In Düsseldorf, we have the opportunity to meet many customers in a short period of time. Furthermore, many friendships have developed with our partners through the years. Thus, I am not only looking forward to interesting discussions about SIKORA technologies, but also to seeing friends.

Harry Prunk: Every other year, all stakeholders of the wire and cable industry meet in Düsseldorf. Manufacturers, processors, suppliers and providers use this week to discuss technologies, projects and trends of the industry. SIKORA has been participating in the exhibition since 1976, and still today, the wire and cable business is one of our core markets. Therefore, the ‘wire’ is for us the most important trade fair for the wire and cable industry worldwide. In Düsseldorf, we have the opportunity to meet many customers in a short period of time. Furthermore, many friendships have developed with our partners through the years. Thus, I am not only looking forward to interesting discussions about SIKORA technologies, but also to seeing friends.

WCI: At SIKORA, what does Industry 4.0 mean and what are the benefits for the customer?

HP: Industry 4.0 means the intelligent connection of humans, technologies and processes. Thus, production lines can be operated more flexibly and efficiently and the quality of products can be increased. The electrification is growing worldwide and hence, the need for cables. Simultaneously, the requirements of our customers concerning measuring technologies become more diverse. Whereas in the past a classic quality control, meaning the measurement of product parameters online as well as data transfer and diagnosis, were sufficient, nowadays the demands on technologies are more comprehensive. Customers want to intervene in the process early and control it permanently. This is realized by an automatic control of the production line and inline with Industry 4.0. The customer is provided with the relevant information via the SIKORA processor systems or directly by the measuring systems. Furthermore, SIKORA devices have an optional OPC UA interface that enables the transfer of data within all IT systems. With SIKORA systems, our customers receive smart technologies of the future to deliver highest quality and make production lines more efficient.

WCI: What can customers expect from SIKORA’s exhibition booth?

HP: They can definitely expect many innovative measuring, control, inspection, analysis and sorting systems that further optimize production processes. Modern Laser and X-ray technologies measure precisely and reliably product parameters such as diameter, ovality, wall thickness and concentricity. In addition, SIKORA’s product portfolio comprises spark testers for the detection of insulation faults, lump detectors for the detection of faults on the product surface, capacity measuring systems as well as devices for reliable conductor preheating and temperature measurement and control. In addition, visitors will get to know our sophisticated systems for quality assurance of optical fibers in the drawing tower.

Another highlight will be the PURITY SCANNER for online inspection and sorting of plastic material that is used, for example, for the insulation of power cables. The system assures that only pure material is entering the extrusion process and the final product. Furthermore, the PURITY CONCEPT Systems will be presented at the ‘wire’. With this technological innovation, there are devices available for offline inspection and analysis of pellets, flakes and tapes/films. The systems presented are based on X-ray and optical technologies depending on application.

Experience these and many other innovations from SIKORA. Come up to our booth for conversations, technical discussions and enjoy freshly prepared food and refreshments in our lounge area on the second floor.

Medek & Schörner

Marking of Cables and Coating of Optical Fibers

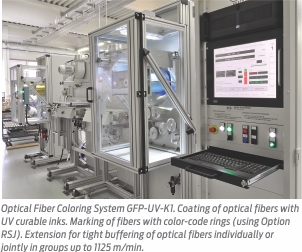

Medek & Schörner, the world market leader in cable marking machines and optical fiber processing lines, will be exhibiting at wire Dusseldorf 2018.

For decades now, Medek & Schörner has been a world market leader in cable marking machines and optical fiber processing lines. As the only company operating in this market segment, Medek & Schörner covers virtually the entire spectrum of machines for marking cables and coating optical fibers; in particular for power, telecom and datacables.

For decades now, Medek & Schörner has been a world market leader in cable marking machines and optical fiber processing lines. As the only company operating in this market segment, Medek & Schörner covers virtually the entire spectrum of machines for marking cables and coating optical fibers; in particular for power, telecom and datacables.

Medek & Schörner will be presenting and demonstrating the following high-performance cable marking machines at the WIRE 2018 Düsseldorf fair:

Cable Marking Machines

- High quality gravure printers (LAN cables, control cables, etc.) for speeds up to 1200 m/min

- Embossing meter markers / hot foil sequential meter markers for highest accuracy of length measurement (power cables, telecommunication cables, optical fiber cables, etc.)

- High performance ring markers for marking telephone wires, switchboard wires, automotive cables, LAN cables

- Video system for monitoring the print quality of fast-running cable printing machines, e.g. allowing real-time inspection for bad quality and/or missing prints

- Laser Marking System for Cables

Optical Fiber Coating Systems

Top speed optical fiber processing systems:

- Optical fiber color coating up to 3000 m/min;

- Ring marking of optical fibers for speeds up to 1280 m/min;

- Tight buffering up to 1300 m/min;

- Fiber ribbon production with excellent ribbon planarity and for speeds up to 1000 m/min;

- CFU Production of compact fiber units

Thanks to the modularity and flexibility of its systems, Medek & Schörner as market leader in coating machines for optical fibers was able to implement other applications, including some outside the field of optical fibers:

- Copper wire insulation with UV varnishes (enameled wire)

- Manufacture of dimension-sensitive precision micro flexible flat cables (FFC) using UV resins

(Booth: Austrian Pavilion 10 / C52-01).

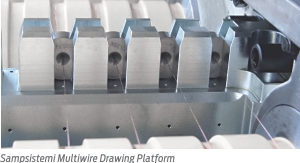

Sampsistemi

Sampsistemi at wire Düsseldorf 2018

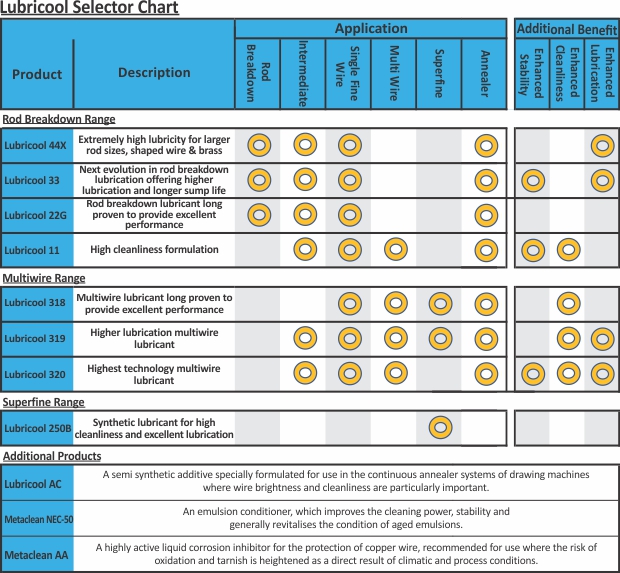

The company will be showcasing number of innovative solutions for the wire and cable manufacturing technology such as Rod Breakdown Platform, Multiwire Drawing Platform, AN Platform, and so on.

The wire show in Düsseldorf (April 16 to 20, 2018) is just around the corner. Sampsistemi looks forward to meeting customers, partners and friends at Hall 9, Booth 9C60 to show the results of its constant strive for precision and excellence, in an effort to make customers’ manufacturing more reliable, efficient and environmental friendly, decreasing production costs and scrap rates while ensuring an excellent wire and cable quality.

A number of innovative solutions for the wire and cable manufacturing technology will be on display. Let’s have a look at some of the most interesting ones.

A number of innovative solutions for the wire and cable manufacturing technology will be on display. Let’s have a look at some of the most interesting ones.

The Sampsistemi Rod Breakdown Platform (RB Platform) is based on the multi-motor technology for rod breakdown machines and annealers. The RB Platform consists of three product segments in the drawing section, R1, R2 and R3, all designed to meet every possible customer requirement depending on their final application (redrawing wire, power cable, enameled wire, flat wire, welding wire etc.) and materials (copper, aluminum and alloys). Horizontal and vertical annealers with contact rings up to 700 mm and annealing current up to 12000 A are available. The product portfolio is rounded out by a wide range of single and double spoolers, with manual and automatic reel changeover, static spoolers and coilers.

The Sampsistemi Multiwire Drawing Platform (DM Platform) and the Multiwire Annealing Platform (AN Platform) is based on the latest advanced technology developed by Sampsistemi, such as slip-recovery, multi-motor technology for annealing, motion control, HMI system and electronic annealing equipment. Aluminium and its alloys are playing an important role in the development of wire and cable solutions for automotive applications. For this reason, Sampsistemi is engaged in a continuous improvement of the whole range of products designed for the multi-wire drawing, in-line annealing, spooling and successive bunching process of aluminium wire.

The DM Platform consists of drawing machines up to 56 wires, with wide outlet wire diameter, from 0.05 to 1.35 mm, and inlet wire up to 2.6 mm. Slip-recovery technology, based on the splitting of gear transmission into two or more independent sections, each one driven by one or more motors synchronised by PLC, allows less wire stress and breakage, a reduced wear of capstans and guiding elements, a better wire quality and a reduction of energy consumption by 10-15%.

The AN Platform includes several technical features, such as improved cooling and drying system, multi-motor technology, adjustable pre-heating length, wire-walker before contact rings and cleaning device on contact rings. The control system is able to set up all production parameters to form a production recipe stored in the HMI panel. The Annealer Platform is completed with the latest developments in annealing technology, such as the electronic equipment that improves the wire surface quality and energy efficiency (PF > 0.90).

With the recent acquisition of Euroalpha, Sampsistemi has enlarged its product portfolio of Rotating Machines, particularly in the large double-twist and single-twist technology. At wire Düsseldorf visitors will have the opportunity to see the new Single Twist EST 1250, characterized by a smooth wire path for high quality strand, dual pintle take-up for reels up to 4500 kg, a low inertia single-arm flyer for high-speed and energy saving, functioning as a back-twist pay-off for multi-pass strand, low maintenance and no foundations or pit required.

As one of the leading companies in the extrusion technology, always guaranteeing an extremely high production output while at the same time ensuring an excellent quality of the final product and the possibility to work a wide range of materials, Sampsistemi is also displaying the SAMP 120-25 Extruder for the LV cable sheathing. This machine is engineered also for HV sheathing cables and fast insulation lines with different compound types.

Moreover, Sampsistemi also produces machines for the rubber market and recently increased its product portfolio due to the acquisition of the Italian company Euro Extrusion. At the wire Düsseldorf, also the silicone extruder ES.60.13D will be shown, featuring a conservation design engineered for easy and practical maintenance, as requested by customers worldwide.

Also on display, a SAMP 80-25 extruder from the Sampsistemi Research & Development laboratory, where the Italian company tests a number of different cable types in realistic production conditions to improve machine performances and supply its customers with cable samples.

All extruders on show will feature solutions developed together with CJ TEK, Sampsistemi’s Swiss Technology Partner for Extrusion Crossheads, who will be a co-exhibitor at the show, displaying a number of high-technology, innovative crossheads for many different applications.

It is worth stressing that all Sampsistemi machines are developed according to the most recent innovations of Industry 4.0, in order to allow customers to manage all production and maintenance data remotely in an easy and convenient way.

(Booth 9C60; Hall 9)

Cable Tapes UK Ltd

Martin Van Der Zwan Is the New Chairman of the IWMA

Cable Tapes UK Ltd, market leading supplier of mica tapes to the cable industry, is delighted to announce that Martin Van Der Zwan is the new Chairman of the IWMA. Martin Van Der Zwan has taken over from Amanda Shehab as chairman.

With more than 40 years of industry relevant experience, Martin Van Der Zwan’s expert knowledge of cable manufacturing and supply chain management will be an invaluable asset to the IWMA. Having sat on the executive committee at the IWMA since 2014, Martin is thrilled to take on this position of increased responsibility for the next three years.

With more than 40 years of industry relevant experience, Martin Van Der Zwan’s expert knowledge of cable manufacturing and supply chain management will be an invaluable asset to the IWMA. Having sat on the executive committee at the IWMA since 2014, Martin is thrilled to take on this position of increased responsibility for the next three years.

Martin Van Der Zwan has taken over from Amanda Shehab as chairman and hopes to continue her excellent work and will promote the new technology, education and growth in the industry to even higher levels.

Founded in 1970, the International Wire & Machinery Association is the world’s largest and most influential corporate association for the wire, cable and wire product industries. Its events and conferences offer an international forum for technological advance and best practice.

“We actively encourage industry stars of the future through the IWMA’s Educational Trust Fund” said Martin Van Der Zwan. “This amazing opportunity offers newcomers an opening to gain new skills which otherwise might not be available. All members benefit from the IWMA and the international platform for exchange of technology it delivers. I look forward to promoting more regular focused meetings for the industry and ensuring that our library of past technical conference papers provides the best reference resource available.”

Martin Van Der Zwan will be ensuring that members continue to enjoy excellent publicity openings through the association’s Wire & Cable News newsletter, and the lively and informative website. Martin will be promoting even greater prospects for members to shape their own futures, ably assisted by the IWMA and its unrivalled opportunities for networking and collaboration.

With Martin Van Der Zwan at the helm, the IWMA has an exciting three years ahead to look forward to, and even brighter and more prosperous opportunities for the Industry as a whole. Watch this space as the IWMA goes from strength to strength with Martin’s vision and expertise taking them to the next level.

Ajex & Turner

Ajex & Turner Wire Technologies to Participate in wire 2018

The company will showcase breakthrough achievements such as VNT nano dies, lubricants, pressure dies, PCD & TC busbar dies, sector shape dies, crossheads, buncher bows, various models of ultrasonic cleaner, in-house polishing & re-grinding machines. These are among the products which are taken a way ahead in terms of technology, quality and innovation.

Ajex & Turner make the extrusion tips and dies in various shapes and sizes and are made up of alloy steel and special custom materials. The company uses very high quality rust free steel with tested ideal OD and ID concentricity. The tightly maintained concentricity allows wire insulators to meet the demands of today’s super thin-wall constructions. These tools are made in alloy steel, carbide and diamond as per customer’s requirement.

Ajex& Turner Wire Technologies has been an integral part of Wire & Cable show since past 30 years and this time at Dusseldorf fair 2018, the company is looking forward to showcasing its new developments as an ultimate opportunity to attract its target customers.

Being a one stop shop for major consumable requirements for any wire and cable manufacturing plant the visitors who want a precise quality and troubleshooting for their wire drawing units will surely get benefited.

The extrusion dies are made as per customer’s requirements and can be tubing die, compression die or semi compression die. Ajex & Turner makes tip and die with a mirror polish and no sharp edges to ensure optimal insulation material flow and easy threading, smooth finish on cable.

The extrusion tip & die determines and strictly control the shape and size of the insulating material. State-of-the-art technology and tight concentricity of Ajex & Turner extrusion tools enables to maintain desired and even insulation thickness also saves the material and reduces the scrap. Super-hard diamond inserted in the die, ensure long tool life even at high speeds process.

The end result is an insulated wire with uniform insulation thickness and precise conductor centering that provides the correct electrical characteristics in the finished product.

We also represent Unitek-Austria Crossheads for Indian market.

(Booth 11CO3)

Isinox India

Isinox India to Showcase at wire Dusseldorf 2018

The company will be presenting a range of aluminium alloy and copper magnet superfine wires at Wire 2018.

Isinox india is engaged in manufacturing various grades of aluminium alloy and copper magnet super fine wire. The company has a tradition of following unbeatable quality standards & providing best solutions to our customers. It has well designed quality control equipment to test raw material, in process material and finished wire quality.

Isinox india is engaged in manufacturing various grades of aluminium alloy and copper magnet super fine wire. The company has a tradition of following unbeatable quality standards & providing best solutions to our customers. It has well designed quality control equipment to test raw material, in process material and finished wire quality.

The company’s portfolio includes a vast range of al-mg alloy wires, which can be used for braiding, shielding, in flexible coaxial cable, audio, video cable, vehicle signal cable, network cable, data transmission cable, mosquito nets, lighting conductors, tea bags, staples, paper clips, hangers, pipe hose sanitary fittings, anti-vibration tubes, etc. Its highly skilled production staff remains ever ready to take the responsibility of producing high quality aluminium alloy and copper magnet superfine wires.

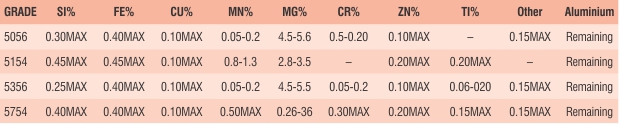

Product Information:

Aluminium/aluminium alloys have strong corrosion resistance. These alloys are sensitive to high temperatures ranging between 200 and 250°C (392 and 482°F), and tend to lose some of their strength. However, the strength of the aluminium/aluminium alloys can be enhanced at subzero temperatures, making them ideal low-temperature alloys.

Product Features:

Bright color and excellent electrical conductivity can bear being blended, good tensile strength, light density and so on.

Chemical Composition:

The following table shows the chemical composition of the few main grades of aluminium/aluminium alloys. Many other grades are also available:

Finishes:

Excellent finishes can be obtained with Al alloy. The following is a list of available finishes

- #4 Finish: A lustrous finish especially applicable for cold heading. This oxide free surface greatly improves tool life and uniformity in metal flow while heading. Product has enhanced, shiny appearance and will anodize well.

- Anodizing Finish: This oxide free surface has specific applications in products that are color anodized or bright dipped as a final operation. It adds a luster to the anodized part and improves corrosion resistance.

- Bright Finish – Clean, chrome-like finish comparable to stainless or chrome finish on steel; improves cosmetic appearance of aluminium wire

Applications:

The aluminium/aluminium alloy is widely used in the manufacture of welded structures, storage tanks, aluminium pads, electrical and telecommunication cables, flexible cables, coaxial cables and pressure vessels. It is also used in salt water service, insect screening, shielding wire for co- axial cable and various round wire products, metal network – nets, mesh, filter etc.

(Booth 11CO3)

AEI MACHINES

AEI MACHINES to Exhibit New Developments for Superiors Quality Stranding at wire Dusseldorf 2018

With 47 years of continuous presence in manufacturing and design of Rigid Stranding Machines, AEI Machines (Associated Engineers & Industrials Ltd.) has become the reliable partner for stranding needs of several reputable cable manufacturers.

AEI MACHINES offers custom-made solutions as per customer’s production requirement for all types of energy cables and conductors. The company remains focused on developing and offering Rigid Stranders to attain excellence in stranding, providing cable manufacturers with machines of robust manufacturing and equipped with the most advanced technological advantages and safety features.

AEI MACHINES offers custom-made solutions as per customer’s production requirement for all types of energy cables and conductors. The company remains focused on developing and offering Rigid Stranders to attain excellence in stranding, providing cable manufacturers with machines of robust manufacturing and equipped with the most advanced technological advantages and safety features.

AEI Rigid Stranders deliver accurate back tension, smooth strand deviation and precise lay control. These features are essentially required for superior quality compacted conductor in case of low, medium and EHV power cables and for high production speeds in case of overhead conductor manufacture.

At WIRE 2018 Düsseldorf (Stand 11 D14), AEI Machines will exhibit its new developments that ensure optimal process efficiency and superior quality stranding. AEI Team shall be looking forward to welcoming visitors from all over the world and showcase the advantages of upgrading to AEI Stranders.

(Booth D14; Hall 11)

CPM GmbH

CPM GmbH to Present Its Software Products and Consulting Work at wire 2018

A special focus will be on latest developments to analyze the development of the temperature distribution in tools at the start and during production.

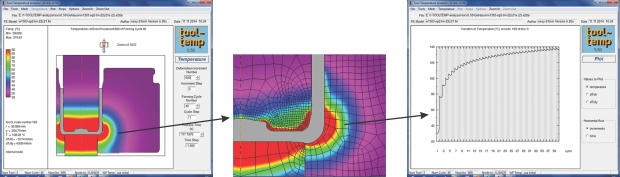

CPM works in technical consulting, research and software development in the area of forging. CPM will present their software products and examples of their research and consulting work. The software products shown will be – eesy-2-form, eesy-form and eesy-DieOpt.

eesy-2-form is a 2D FEA simulation system. It is very easy to handle and proved its reliability in industrial application for more than 16 years all around the world. Latest develop-ments related to tool ware, product failure detection and microstructure analysis for modern materials will be shown.

eesy-form is the 3D add on to eesy-2-form. eesy-form is in use for more than 15 years in cold and hot forging industries. Latest developments in tools analysis, machine setup including complex systems using hydraulic cushions and advanced post-processing will be presented using industrial production examples.

eesy-DieOpt is an established system for design and optimization of tool layouts using multi-ring prestressing systems. CPM will show and explain in detail how such a system will be used together with process simulation to optimize the tooling properties and the tool life.

The main advantage is the most accurate result for the temperature distribution in the forming tools after a high number of forming cycles. Besides, the result of temperature distribution in the forming tools – and especially at the tool surface – after a number of forming cycles the described tool temperature analysis is very suitable to determine the number of forming cycle necessary to reach a more or less steady state situation of the temperature development in the forming tools. This is important when deciding for a suitable tribosystem – or if it seems to be critical during the start-up phase of a forming process – to decide for a preheating of the forming tools.

(Booth 15C36)

Aachener Maschinenbau GmbH

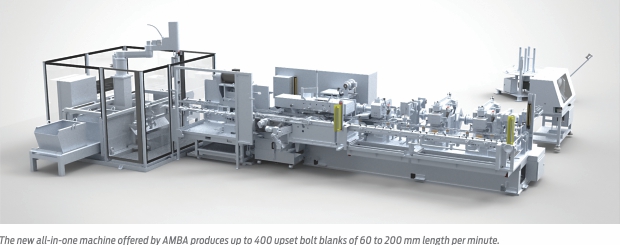

AMBA Premiere at WIRE 2018: Efficient Manufacturing of Bolts of up to 200 MM Length

Bolt blanks with two heads speed up production; new all-in-one machine produces 24,000 bolt blanks per hour.

Aachener Maschinenbau GmbH (AMBA) is going to introduce its new all-in-one machines for the production of up to 200-mm-long bolts at unsurpassed rates. In these machines, several upsetting operations take place simultaneously. Compared to conventional machines, this achieves an increase in throughput many times over – also with bolt heads of complex shapes. Bolts in lengths between 160 and 180 mm are typically produced at a rate of 60 pieces per minute.

Aachener Maschinenbau GmbH (AMBA) is going to introduce its new all-in-one machines for the production of up to 200-mm-long bolts at unsurpassed rates. In these machines, several upsetting operations take place simultaneously. Compared to conventional machines, this achieves an increase in throughput many times over – also with bolt heads of complex shapes. Bolts in lengths between 160 and 180 mm are typically produced at a rate of 60 pieces per minute.

In contrast, the new all-in-one machine offered by AMBA produces upset bolt blanks of 60 to 200 mm length at a much higher rate. The first machine of this new all-in-one design can produce up to 400 bolts per minute, or 24,000 pieces per hour.

The new AMBA machines achieve this dramatic increase in throughput by first upsetting one end of the rod, then rotating the rod and upsetting the opposite end – in an integrated secondary upsetting station the machine. The thus produced bolt blanks have a head at both ends. At the end of the process, they will be cut in half. This means that at a production rate of 180 to 200 pieces per minute the machine actually delivers 360 to 400 bolts.

Manfred Houben, one of the two Managing Directors of AMBA, sees great potential also for the production of bolts with complex head shapes: “To produce heads of complex shapes, we can arrange several upsetting stations in a row to perform several, let’s say, three or four, blows at one end of the bolt blank. This is extremely helpful in order to cater to, for example, the growing demand for increasingly bigger flat heads. As all the upsetting operations take place simultaneously, we can also produce sophisticated head shapes at the same high rates.”

The machines can handle bolts with diameters between 4 and 10 mm, in lengths ranging between 60 and 400 mm, depending on the rod diameter.

The new machines are built according to the all-in-one principle which AMBA also uses in many other machines designs. What makes the machines so special is the fact that all process steps take place within one single machine – everything from the synchronized decoiler of the wire, upsetting of the bolt heads and thread rolling down to placing the finished products in an automated process in transport boxes. As all process steps are mechanically coupled, highest process reliability is guaranteed.

Thanks to the modular design of the machines, additional functions such as pinching of the tip, machining or milling of grooves or turning and deburring of tube ends can be easily integrated.

(Booth C36; Hall 15)

EJP GmbH

EJP’s Premiere at wire 2018: Linear Motors Enhance Precision of Drawing

At wire 2018, EJP is going to introduce the new generation of its CDS-TQ series of combined drawing machines.

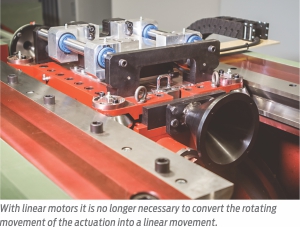

By using a linear motor to actuate the drawing jaws, EJP has significantly simplified the mechanical design and the movements of the drawing jaws. Thus EJP achieves higher precision in bar, tube and profile drawing, while improving ease of operation and reducing maintenance requirements.

By using a linear motor to actuate the drawing jaws, EJP has significantly simplified the mechanical design and the movements of the drawing jaws. Thus EJP achieves higher precision in bar, tube and profile drawing, while improving ease of operation and reducing maintenance requirements.

Two years after EJP introduced drawing machines with servoelectrically actuated drawing jaws as an alternative to hydraulic actuation, the company has now taken their systems to the next level. With linear motors it is no longer necessary to convert the rotating movement of the actuation into a linear movement. The advantages of this solution: no indirect transmission of forces, fewer movable parts and higher-precision drawing of bars, tubes and profiles.

The linear motor design is a further development of the servoelectric actuation of the drawing jaws, a design that has proved highly successful in more than ten machines built. In the combined drawing machines featuring the new – patent-pending – system, the motors control the actuation of the jaws in real time based on the contour of the drawing cam, closing and releasing the jaws as required.

Jacques Paraskevas, Managing Director of EJP, is committed to offering his customers the best solution for their specific requirements: “All three drive solutions – hydraulic, servoelectric and linear motor based – have their advantages depending on the application. Therefore we will present all three of them at WIRE 2018: one drawing unit equipped with the new linear motors and one fitted with two drawing carriages, of which one is equipped with a servomotor and one with hydraulic cylinder. This hands-on display will allow us to discuss with the trade fair visitors in a best possible way what would be the optimal solution for their specific application.”

The linear motors can be used in the complete portfolio of combined EJP drawing machines operating with drawing forces ranging between 2 and 46 tons and producing finished bars with diameters from 2 to 60 mm.

(Booth A12; Hall 9)

Eder Engineering

Eder Engineering at wire Dusseldorf 2018

Eder is presenting its various technologically leading equipments at the exhibition.

Offering innovative and high value added concepts with over 70 years of expertise in the field of reconditioning die working equipments, EDER-Austria is sustaining and developing its distinctive advanced position across the globe and is presenting its various technologically leading equipments at Hall 10/C42-01 at Wire Duesseldorf 2018.

Offering innovative and high value added concepts with over 70 years of expertise in the field of reconditioning die working equipments, EDER-Austria is sustaining and developing its distinctive advanced position across the globe and is presenting its various technologically leading equipments at Hall 10/C42-01 at Wire Duesseldorf 2018.

Some examples of unmatched EDER machines at WIRE 2018 that will be presented life by EDER´s staff and on a video wall:

ETC-1/HF: Efficient tungsten carbide die grinding and polishing equipment with a very large work range of between 0.70 up to 20 mm dia.

USP-TWIN: Particularly for refurbishing of the continuously growing quantity of PCD dies in use at multi-wire drawing machines, a unique Ultrasonic machine, model USP-TWIN, with two workstations has been developed, which can efficiently work all die-sizes in a large range between 0.05 up to 8.0 mm dia. It can be operated by one only person, same time doubling output.

ETC-2 LS: for sizing and polishing tungsten carbide dies in the larger bore size range, of between 1.0 up to even 40 mm dia.

A new larger ETC-3L unit even works round TC dies with bigger bore-sizes up to 70 mm dia. Additionally, some special die-workshop ancillary devices and other machines also will be demonstrated at the Eder stand.

The company is eager to discuss at its booth industry’s new trends and concepts, particularly showing ultimate solutions for the efficient reconditioning of dies and would be pleased to visualize the many benefits, outstanding potentials and capabilities of EDER machines.

(Booth C42- 01; Hall 10)

SIKORA

SIKORA at the wire Dusseldorf 2018

The wire 2018 will take place from April 16 to 20, 2018, in Düsseldorf and again, SIKORA will present innovative measuring, control, inspection, sorting, and analysis systems from its extensive product portfolio. On the exhibition booth 9A41, with a space of 200 m² (240 y²) on two levels, visitors can discover the most recent technological innovations for quality control and process optimization for the wire and cable, optical fiber as well as plastics industries.

The wire 2018 will take place from April 16 to 20, 2018, in Düsseldorf and again, SIKORA will present innovative measuring, control, inspection, sorting, and analysis systems from its extensive product portfolio. On the exhibition booth 9A41, with a space of 200 m² (240 y²) on two levels, visitors can discover the most recent technological innovations for quality control and process optimization for the wire and cable, optical fiber as well as plastics industries.

PREHEATER 6000 TC: Temperature controlled conductor preheating for an optimal adhesion of the insulation

PREHEATER 6000 TC (Temperature Controlled) is the intelligent solution for a precise preheating of the conductor to the nominal temperature. A reliable conductor preheating during the production of high-quality cables, especially for automotive and data cables, is essential to guarantee an optimal adhesion of the insulation on the conductor respectively a controlled foaming. Reproducible processes are the result that contributes to an increase of quality and productivity.

WIRE-TEMP 6000: Self-sufficient temperature measurement system

The WIRE-TEMP 6000 measures continuously and precisely the conductor temperature – online and contactless. The measuring device is available for product diameter from 0.32 to 50 mm (0.01 to 2“) and therefore, suitable for quality assurance in high voltage and data cable lines. The measurement of the temperature is independent of the cross section, material, surface structure, and speed. Especially interesting is the thermal image sensor in an infrared camera that precisely provides the surface temperature without any calibration, and therefore, reliable values for the control of a conductor preheating.

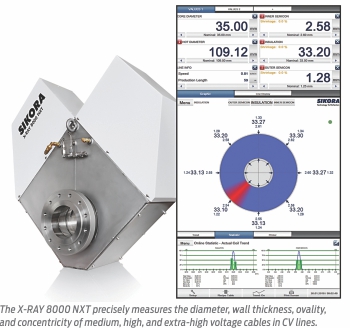

X-RAY 8000 NXT: X-ray technology measures diameter, wall thickness, and concentricity for the medium and high voltage cable production

A highlight at the SIKORA exhibition booth is the X-RAY 8000 NXT – the worldwide industrial standard for quality assurance of medium, high and extra-high voltage cables in CV lines. It measures the concentricity, wall thickness, diameter, and ovality of up to three layers of XLPE and EPR isolated cables during production. Measuring values for the centering of the injection tools and control are available immediately after the starting of the line. The multi-sensor technology (MST) and two high-speed scanners ensure a reliable online measurement. With each single scan, the MST measures the movement of the cable, compensates vibrations and provides double the number of measurements.

X-RAY 6000: Measurement of wall thickness, concentricity, diameter, and ovality in jacketing lines

For continuous quality control during the insulation or jacketing of conductors and cables, the X-ray measuring devices X-RAY 6000 as well as X-RAY 6000 PRO are recommended. Both systems precisely provide reliable measuring values regarding diameter, wall thickness, concentricity as well as ovality for a reproducible product quality. Layer thicknesses of any kind of material are measurable. A maximum of productivity is achieved by the automatic control of line speed and extruder rpm.

LASER Series 2000/6000: Diameter measurement on the highest level

In extrusion lines, the devices of the LASER Series 2000 and LASER Series 6000 are indispensable components for a diameter measurement on the highest level. Furthermore, the classic and high-end devices are used in rewinding lines for the wire drawing. They stand out by their high precision and continuous functionality without calibration or maintenance times. Due to up to 5,000 measurements per second/per axis, the LASER Series 6000 impresses with the highest single value precision for an efficient line control. The integrated lump detector function ensures a detection of irregularities on the product surface of transparent and non-transparent materials. In addition to standard interfaces, the device series provides OPC UA, and therefore, is best equipped for “Industry 4.0”.

In extrusion lines, the devices of the LASER Series 2000 and LASER Series 6000 are indispensable components for a diameter measurement on the highest level. Furthermore, the classic and high-end devices are used in rewinding lines for the wire drawing. They stand out by their high precision and continuous functionality without calibration or maintenance times. Due to up to 5,000 measurements per second/per axis, the LASER Series 6000 impresses with the highest single value precision for an efficient line control. The integrated lump detector function ensures a detection of irregularities on the product surface of transparent and non-transparent materials. In addition to standard interfaces, the device series provides OPC UA, and therefore, is best equipped for “Industry 4.0”.

SPARK 6000: Safety for every cable production

SIKORA offers a complete program of direct current (DC), high frequency (HF) and alternating current (AC) spark testers. Already during the extrusion, the insulation of wires and cables is tested with the high voltage testing devices and possible insulation faults are detected and documented in a timely manner. Further application areas are rewinding lines. For the testing, the dry cable running through the bead chain electrode of the spark tester is exposed to the selected test voltage. Therefore, faults in the insulation are reliably detected.

CENTERVIEW 8000: Measurement of concentricity, diameter, and ovality

With the CENTERVIEW 8000, SIKORA presents a measuring system for the non-contact, online 8-point-eccentricity, 4-axes-diameter and 8-point-ovality measurement of coax cables, LAN cables as well as automotive and installation cables to the global public. Technical highlights of the CENTERVIEW 8000 are the graphic visualization of measuring values as a scatter plot that shows the distribution of short-term variations as well as the automatic positioning of the gauge head to the cable position for highest reliability. A further feature is the measurement of micro-coax cables with a diameter range from 0.1 to 10 mm (0.004 to 0.4”).

FIBER Series 6000: Online quality control of optical fibers in the drawing tower

By means of a drawing tower model, SIKORA presents live its broad portfolio of measuring systems for quality control of optical fibers at different positions. There will be systems presented for the measurement of the diameter and the position of the naked and coated fiber as well for the determination of the tension. Furthermore, gauge heads are displayed for the measurement of the fiber temperature at the hot position of the drawing process, to determine the fiber temperature for the control of the furnace, and at the cold end, to exactly dose the Helium used for the cooling, and therefore, to save costs. In addition, a gauge head for the measurement of the concentricity of the coating as well as for the detection of lumps on the surface of the coated fiber is exhibited.

By means of a drawing tower model, SIKORA presents live its broad portfolio of measuring systems for quality control of optical fibers at different positions. There will be systems presented for the measurement of the diameter and the position of the naked and coated fiber as well for the determination of the tension. Furthermore, gauge heads are displayed for the measurement of the fiber temperature at the hot position of the drawing process, to determine the fiber temperature for the control of the furnace, and at the cold end, to exactly dose the Helium used for the cooling, and therefore, to save costs. In addition, a gauge head for the measurement of the concentricity of the coating as well as for the detection of lumps on the surface of the coated fiber is exhibited.

PURITY SCANNER: Online inspection and sorting of XLPE and semiconductor pellets

A further highlight at the wire is the PURITY SCANNER for online inspection and sorting of plastic pellets that are used for the insulation of medium, high and extra-high voltage cables as well as onshore and offshore cables. The unique combination of an X-ray camera with an optical camera system is currently the only technology that reliably detects contamination on the surface as well as inside of plastic pellets. Contaminated pellets are automatically sorted out.

PURITY CONCEPT Systems: Offline inspection and analysis of pellets, flakes, and films/tapes

SIKORA engineers developed the PURITY CONCEPT Systems for small material throughputs and applications where sample testing or an incoming goods inspection is sufficient. These analysis devices are alternatively equipped with X-ray technology, optical cameras or infrared sensors and detect contamination in pellets, flakes, and tapes. For example, the PURITY CONCEPT Systems are used to analyze pellets that have been detected and sorted out by the PURITY SCANNER. Another typical application is the testing of tapes that are used when manufacturing factory joints. The interplay of online and offline inspection and analysis provides an absolute control of the material purity as well as the development of a database to further improve processes and avoid future contamination.

Further devices at the SIKORA exhibition booth

- LUMP 2000: Measuring technology for the detection of lumps and neckdowns in two or three measuring planes with double sensor technology

- ULTRATEMP 6000: Non-contact temperature measurement of the polyethylene melt

- CAPACITANCE 2000: Innovative capacitance measurement with multi-zones technology as well as integrated FFT and SRL analysis

- Display and control systems: Powerful ECOCONTROL 6000, 1000, and 600 processor systems as well as low-cost display and control devices REMOTE 2000 and DISPLAY 2000

(Booth A41; Hall 9)

EROCARB SA

EROCARB SA to Showcase Its High Precision Cross-heads and Tooling for Polymer Extrusion at wire 2018

The company is going to put first time on the show the new version of crossheads E2, E4 and E14 family with reduced front head length in order to ease access to the front die face.

Erocarb is a global provider of crossheads and tooling for polymer extrusion for wire/cable/pipe and tube industries for more than 30 years. The company is located in Giez, Switzerland and delivers products all over the world.

Erocarb is a global provider of crossheads and tooling for polymer extrusion for wire/cable/pipe and tube industries for more than 30 years. The company is located in Giez, Switzerland and delivers products all over the world.

Erocarb merge high precision manufacturing with technical know-how in polymer extrusion. During 2017, two new CNC 5 axis milling machines were added to the machine shop. The result is a rise of production and an improvement on precision.

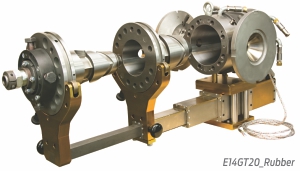

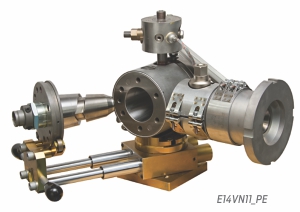

Erocarb delivers crossheads intended for products with flat, round or even various geometry shape. Extrusion lines for insulation, sheathing/jacketing, filling-sheathing, triple layer on CV line are implementing Erocarb crossheads with great results. Erocarb also produces crossheads for flat ribbon, insulation, medical and irrigation tube.

The short conical crossheads, typical from Erocarb, achieving a high concentricity in fixed-centring or with the fine tuning device drives the success. Larger models are using fix and manual centring. The distributors are defined for the specific polymers to be used: PE, PVC, TPU, HFFR, EPDM, etc.

The short conical crossheads, typical from Erocarb, achieving a high concentricity in fixed-centring or with the fine tuning device drives the success. Larger models are using fix and manual centring. The distributors are defined for the specific polymers to be used: PE, PVC, TPU, HFFR, EPDM, etc.

Many Hastelloy® crossheads are also manufactured for extrusion of fluoro-polymer. In this case additional heaters will be implemented in order to guarantee proper temperature level for FEP, PFA, ETFE, etc.

Beside standard crossheads, Erocarb is also selling tailor made solutions designed by internal engineers. In any case, the projects are submitted to customers before any manufacturing process. 3D views and models may allow the check of solutions at an early stage of the project and save time during assembling process.

Complementary to the crosshead series, the maintenance modules ETEL save time and reduce wear. Cleaning process and exchange of tooling are done easily and safe.

Complementary to the crosshead series, the maintenance modules ETEL save time and reduce wear. Cleaning process and exchange of tooling are done easily and safe.

Either with standard or specific devices, Erocarb is focused on customer’s needs. Precision and traceability allow also Erocarb to deliver spare parts for genuine extrusion equipment delivered over 20 years ago!

First at Wire 2018:

- New version of crossheads E2, E4 and E14 family with reduced front head length in order to ease access to the front die face.

- New tiny E2 crosshead with skin and stripe(s) for high speed production

- New versatile E4 crosshead for skin-foam-skin and stripe(s) for high speed production.

(Booth C60; Hall 10)

Bartell

Bartell at WIRE 2018

Bartell will premier its newest production solution, the ArmourLock ST-4. Speed, product quality, productivity, ease of set-up, and reduced maintenance are the foundations of the ArmourLock design.

For over 78 years, Bartell Machinery Systems has brought to the wire industry renowned production solutions such as cantilever take-up and pay-offs, tubular stranders, planetary stranders and the CEECO advanced roll forming system. To continue the tradition of innovation we listened to our customers, understood their needs and set out to create a new manufacturing system that not only focuses on providing leading production metrics but how people interact, engage, and connect with manufacturing systems.

For over 78 years, Bartell Machinery Systems has brought to the wire industry renowned production solutions such as cantilever take-up and pay-offs, tubular stranders, planetary stranders and the CEECO advanced roll forming system. To continue the tradition of innovation we listened to our customers, understood their needs and set out to create a new manufacturing system that not only focuses on providing leading production metrics but how people interact, engage, and connect with manufacturing systems.

On the stand at this year’s show, Bartell will premier its newest production solution, the ArmourLock ST-4. Speed, product quality, productivity, ease of set-up and reduced maintenance are the foundations of the ArmourLock design. This advanced system incorporates a redesigned drive system, 50% increase in raw material capacity, off-line tooling setup and advanced ergonomics to create a system that stands apart. Also featured at the stand will be the new Bartell 42” caterpuller (pictured). With its advanced servo drive system, dual cylinders the caterpuller delivers improve line control and more consistent product quality. From stranding to coiling and everything in between Bartell works to deliver innovative solutions that drive the future of manufacturing, one machine at a time.

Bartell Machinery Systems is a global leader in providing highly-engineered industrial manufacturing equipment for the Tire & Rubber, Oil & Gas, and Wire & Cable industries. Bartell has delivered innovative solutions to leading manufacturers since 1940, with over 8,500 machines installed worldwide. Bartell is headquartered in Rome, NY with sales and service capability around the globe.

(Booth B74; Hall 9)

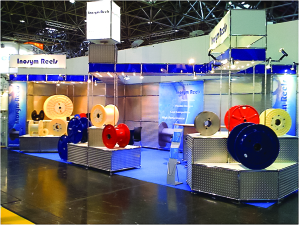

Inosym reels

Inosysm’s Specialized Steel & Plastic Reels to Feature at wire 2018

Inosym has been supplying reels to the cable and wire industry for 16 years and to over 55 countries.

Specialising in Steel and Plastic reels that are manufactured to European and USA standards, Inosym can offer reels to meet all the varying needs of the modern manufacturing plants. Inosym is committed to providing our customers with world class quality reels and bobbins at competitive prices.

Specialising in Steel and Plastic reels that are manufactured to European and USA standards, Inosym can offer reels to meet all the varying needs of the modern manufacturing plants. Inosym is committed to providing our customers with world class quality reels and bobbins at competitive prices.

Inosym reels were developed to provide cable and wire manufacturers with a product that was realistically priced and of high quality. The company believes that it is achieving this goal and is assisting its customers in reducing capital expenditure and increase profits.

Product Examples:

- ABS plastic reels from 250mm to 1000mm for insulating, group twinners, stranding, bunching, jacketing.

- MF (Metal Flange) pressed metal process reels come in sizes from 100–1250 mm and are made from high-quality steel plate and tube. Applications include universal take-up and payoff reels, bunching, stranding, insulating and jacketing.

- SM (Semi Machined) double-wall high-speed reels come in sizes from 315–1250 mm and are made of high-quality steel plate and tube. Applications include drawing, bunching, stranding and insulating.

- FM (Fully Machined) steel high-speed reels in sizes ranging from 100– 1000 mm and manufactured from high-quality steel plate and tube. Applications include high-speed single-wire drawing, high-speed multi-wire drawing, bunching and enamelled wire coating.

- SD (Steel Drum Reels) are large steel process and shipping drums available in sizes ranging from 800 to 4500 mm. SD Steel Drum Reel options include flat sided flanges, corrugated flange and break-down reels. Applications include drum twisting, stranding, insulating and jacketing.

With more than 40,000 square meters of production space, Inosym can provide its customers with rapid delivery of both large and small reel orders.

(Booth D52; Hall 11)

Aim Inc.

Aim to Unveil New Benders and Accessories at wire 2018

Its unparalleled capabilities include real, independent 3D twin-head forming, “single-head” part forming, off-plane 2D and 3D bending, and no minimum center clamp length.

Its unparalleled capabilities include real, independent 3D twin-head forming, “single-head” part forming, off-plane 2D and 3D bending, and no minimum center clamp length.

During the past few years, AIM has developed new benders and accessories that it will unveil at Wire 2018. Its unparalleled capabilities include real, independent 3D twin-head forming, “single-head” part forming, off-plane 2D and 3D bending, and no minimum center clamp length.

From Aim’s patented hybrid forming solution, the Synchro AFM line, capable of unmatched versatility, fast output and low cost maintenance to its newest innovation in wire bending, upgraded and updated 2D and 3D CNC wire bending solutions, single and double bending head machines with Robotics integration and complete automated cells which take wire from coil, form, weld, punch and systematically arrange the finished parts while providing total automated digital production reporting.

(Booth 11A21; Hall 11)

Gauder Group

Gauder Group at WIRE 2018

All three divisions, viz. Rotating Machines, Second-hand machines, and Customer Services will be showcasing at the event.

POURTIER

POURTIER, member of the Gauder Group develops and produces heavy-duty rotating machines to produce all types of power and control cables.

POURTIER, member of the Gauder Group develops and produces heavy-duty rotating machines to produce all types of power and control cables.

With more than 700 Drum Twister and 120 Rigid stranding and Planetary lines commissioned all over the world, Pourtier remains THE leader for machines for Low and Medium voltage up to High and Extra-high Voltage Power Cable.

Indeed, always in touch with its customer’s needs, Pourtier still develops equipment for overhead conductors (including ACCC™ , ACSS-TW and ACSR-TW with trapezoidal wires) as well as underground HV & EHV cable AC type (high quality Milliken conductor) or submarine cable DC type (extra large conductor either compacted or made of Trap wire).

POURTIER is also focused on tailored designed/made equipment used in submarine, umbilical cables and oil & gas application. On the booth, you will discover the “jumbo reel – 1000 mm” planetary machine designed for steel wire armouring of long length power submarine cable

POURTIER and its sister company SETIC, also provide the complete range of Single twist machines from 630 mm to 2500 mm. A 1250 mm single twist will be exhibited illustrating the versatility (control, instrumentation, data, battery… cable) and flexibility (laying-up, stranding, wire armouring process) of these solutions.

On the booth will be one 1000 mm cradle for Planetary strander & 1250 mm Single twist machine.

SETIC

SETIC member of the Gauder Group designs, manufactures and supplies high quality double twist bunchers/stranders for low voltage conductors and cables, automotive industry as well as complete solutions to produce special/LAN cables with enhanced performances (in one step or two steps according to product mix).

Leader in data and special cable manufacturing solutions, Setic will exhibit one complete 800 mm pairing/ Quadding line with Two High Speed Double Positions Backtwist Pay-off.

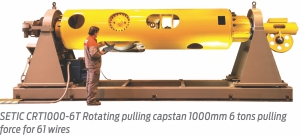

Since the last wire show, Setic has successfully developed, designed, delivered and commissioned several 2000 mm double twist lines, offering to its customers high performances compared to the same category of equipment (wide range of productions by using the machine stand alone or together with an additional external capstan). Illustrating this success story, Setic will exhibit on the show one 1000 mm Rotating pulling capstan with a pulling force of 6 tons for stranding of 61 wires (Cu/Al).

Since the last wire show, Setic has successfully developed, designed, delivered and commissioned several 2000 mm double twist lines, offering to its customers high performances compared to the same category of equipment (wide range of productions by using the machine stand alone or together with an additional external capstan). Illustrating this success story, Setic will exhibit on the show one 1000 mm Rotating pulling capstan with a pulling force of 6 tons for stranding of 61 wires (Cu/Al).

SETIC and its sister company Pourtier, also provide the complete range of Single twist machines from 630 mm to 2500 mm. A 1250 mm single twist will be exhibited illustrating the versatility (control, instrumentation, data, battery… cable) and flexibility (laying-up, stranding, wire armouring process) of these solutions.

SETIC and its sister company Pourtier, also provide the complete range of Single twist machines from 630 mm to 2500 mm. A 1250 mm single twist will be exhibited illustrating the versatility (control, instrumentation, data, battery… cable) and flexibility (laying-up, stranding, wire armouring process) of these solutions.

On the booth : Backtwist Pairing / Quadding 800 mm / AST1250 High speed Single twist assembling machine / CRT1000-6T Rotating pulling capstan 1000mm 6 tons pulling force for 61 wires

DALOO

Since now 8 years, DALOO, part of the rotating machines division of the Gauder Group, is representing the medium cost solution for all cable producers who are looking for a solution with basic functions with affordable prices, simple design by keeping efficiency, and steady quality controlled all along the manufacturing process.

Its complete stranding lines and accessories for the production of power and communication cables are delivered worldwide throughout a complete range of machines such as rigid cage stranders, taping lines, rewinding lines, take-ups and pay-offs, pulling caterpillars.

Its complete stranding lines and accessories for the production of power and communication cables are delivered worldwide throughout a complete range of machines such as rigid cage stranders, taping lines, rewinding lines, take-ups and pay-offs, pulling caterpillars.

The designs as well as the manufacturing in its new facility (still in Changzhou) are based on European experience (proven Gauder Group methods) following strict quality criteria.

On the booth: All our team presenting DALOO activities and available for you during the show!

GAUDER

GAUDER Group Belgium, on which the Gauder Group was founded, is at the head of the largest stock of machines for the wire and cable industry in Europe. “Creating solutions together”, the company is the ideal partner to set up “ready to manufacture processes” from its 1000+ machinery warehouse (drawing, stranding/cabling, screening/taping/armouring, wire coating, extruding, coiling/rewinding, …) for the production of wires, conductors, cables, ropes or steel products.

Gauder Group, Belgium is providing professional and economical solutions to his customers for complete plant reselling (dismantling/complete cleaning and derusting/ painting/assembling/adding of new accessories).

Gauder Group, Belgium is providing professional and economical solutions to his customers for complete plant reselling (dismantling/complete cleaning and derusting/ painting/assembling/adding of new accessories).

Last but not least, the company markets new MAPRÉ extruders ranging 38 – 150 mm available with accessories. A free shuttle service is organized daily from the booth, upon request, to discover the stock of equipment displayed in 20,000 sqm warehouses as well as the workshop in activity.

On the booth: All our team presenting GAUDER Group Belgium activities and available for you during the show!

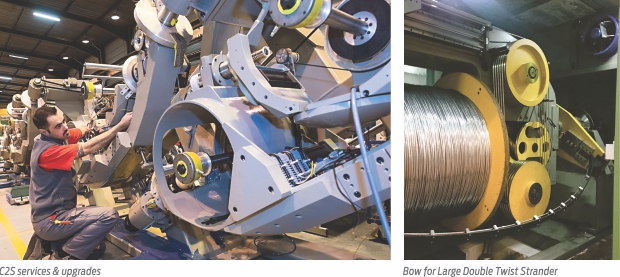

C2S Service & Bows by Gauder Group

ALL BRANDS

C2S division of the Gauder Group takes care of all wire & cable production lines, whatever the brand of the rotating equipment. Rich of a long and successful experience, C2S has recently absorbed BOW TECHNOLOGY, and enlarged its offer with high tech bows and components.

SPARE PARTS

70,000 spare parts references are distributed worldwide through 4 logistic platforms. Our customers benefit of our integrator’s prices.

SERVICE

A team of 55+ technicians is continuously trained to manage troubleshooting and urgent repairs, and the division also offers dedicated services such as periodical visit contracts, transfer and restart operations, training and consulting.

UPGRADES

C2S is being assigned upgrading projects on all brands Wire and Cable equipment, also for special and customized projects (mechanical/electrical interventions, or process improvements with know-how transfer).

BOWS

C2S is the right partner for everyone concerned by a higher level of performances and extended lifetime of double twist equipment. A wide range of state of the art bows is available for different kinds of productions: pairing/ quadding of insulated cables, automotive or special bare copper conductors, and copper/aluminium cords. Without forgetting the exclusive and patented GreenBow2+ that enables high energy savings for bunchers, and simplifies a lot maintenance operations. n

On the booth: A wide range of all sizes bows – including the “GreenBow2+” – for all brands. All Gauder’s team presenting C2S activities and available for customers during the show !

(Booth E40; Hall 10)

SANT ENGINEERING INDUSTRIES

Maker of All Types of Plastic and Cable Machinery

SANT’s 5 decades of experience, state-of-the-art infrastructure, out of the box thinking, technological superiority, advanced processing equipment, team of highly proficient experts and its commitment to ensure highest standards of quality has helped it deliver the world class cable machinery to the needy world.

SANT ENGINEERING INDUSTRIES founded in the year 1966 by Mr. Krishan Lal Malhotra is the leading manufacturer and exporter of all types of plastic and cable machinery worldwide and is committed to fostering excellence in this field. Now under the innovative leadership of Charanjeev Malhotra, the company is setting new trademarks.

SANT ENGINEERING INDUSTRIES founded in the year 1966 by Mr. Krishan Lal Malhotra is the leading manufacturer and exporter of all types of plastic and cable machinery worldwide and is committed to fostering excellence in this field. Now under the innovative leadership of Charanjeev Malhotra, the company is setting new trademarks.

The company is also proud of its presence in the global market and export of our various products and for providing complete plastic and cable machinery solutions. It is already a member of esteemed foundations like NSIC, IWMA (International wire machinery association), EEPC, etc.

Rigorous quality checks are conducted during all production processes to ensure international standards, design, accurate products, features, performance, high scalabilty and durability of our products. Its experience in manufacturing and customer satisfaction along with a comprehensive range of products has earned us the loyal patronage of our clients. The company is committed towards keeping up with latest international technological advancement and providing optimum solutions to our clients.There is always the question whats coming and whats next?

SANT Engineering is a regular exporter of cable and plastic machinery and it is now heading to make its global presence as an industry leader by 2020. Our dedication and urge to give a major hand in this industry will definitely lead us to a global leader. Sant is here to serve the whole cable industry and have a small share in this industry.

KIESELSTEIN

Solutions Individually Engineered

KIESELSTEIN shows portfolio – apart from machines at wire 2018.

From 16th to 20th April 2018 KIESELSTEIN, the manufacturer of wire drawing machines from Chemnitz, will participate in the wire show in Düsseldorf which is the most important trade show of the wire industry. At their booth D22 in hall 10, they will not only show one exhibit which will be a drawing block for the production of trolley wire with a preceding shaving unit. Moreover, the Chemnitz’ company will show how they will meet the increasing requirements of the plant operators in terms of service engineering in connection with their plants by implementing their digital solutions.

The main topics at the booth will be the technological competency in machine engineering and the wide range of services that KIESELSTEIN is able to offer.

Of special interest to the show visitors are the various technologies of wire production where KIESELSTEIN possesses high competency: From shaving of steel, aluminum or titanium wire, hot drawing of difficulty transformable materials, drawing of round and profiled wire, wet drawing to the thermal treatment as a process integrated in the wire production and the coating of wire – KIESELSTEIN offers different technological ideas which can be implemented in individual specific solutions for each customer.

Another topic will be the processing of wire, e. g. the weaving of wire into large wire meshes, the cutting of wire mesh and the patented 3D wire structure called strucwire®.

The service range of KIESELSTEIN comprises drawing and shaving tests on their own production plant, which is also available for contract processing. The supply of spare parts for existing plants, analysis and optimization of production processes in the wire industry, remote diagnosis of working plants as well as retrofit belong to the scope of services. For new investments, KIESELSTEIN offers comprehensive consultancy, engineering of plants and development of suitable tools as well as support during commission and guidance during trial operation.

One of the highlights to be presented at the booth is a 3D-printer that will print parts for an add-on kit for soap boxes which improves the supply of drawing lubricant for the transforming process. In addition the drawing block which will be exhibited can be viewed in detail through a Virtual Reality application opening the way to new opportunities for plant operators.

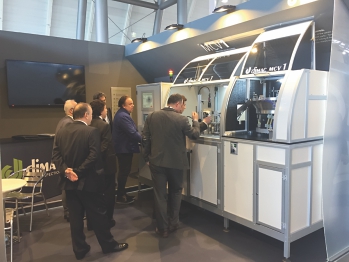

DIMAC

What’s Brewing at DIMAC for wire 2018?

The company will showcase the iconic MCV rotary table-based series on its stand.

The countdown is on: from 16th to 20th April 2018, the world’s most important trade fair for the wire and cable industry takes place. And Dimac aims to be one of the top players. Committed to revolutionize the fasteners inspection technology since 1988, the family-owned company is today recognized as one of the most reliable benchmark for the fasteners manufacturers looking for 100% quality.

The countdown is on: from 16th to 20th April 2018, the world’s most important trade fair for the wire and cable industry takes place. And Dimac aims to be one of the top players. Committed to revolutionize the fasteners inspection technology since 1988, the family-owned company is today recognized as one of the most reliable benchmark for the fasteners manufacturers looking for 100% quality.

Dimac CEO Massimo Agrati says, “We will present a number of technological highlights for our special 30th anniversary. We are proud of the route we have driven along, during these years in a highly competitive market that sees frequent innovations. Our in-house research and development team is constantly looking to improve our product offerings to better meet and exceed our customers’ expectations.”

And Dimac always strives to offer the world’s best machines for today and tomorrow’s application needs. At the Brand’s stand – 15H11, HALL 15 – the iconic MCV rotary table-based series will be on show. The cherry-picking visitors’ most demanding tastes will be satisfied experiencing the latest technologies and state-of-the-art inspection and sorting machinery live in action.

And Dimac always strives to offer the world’s best machines for today and tomorrow’s application needs. At the Brand’s stand – 15H11, HALL 15 – the iconic MCV rotary table-based series will be on show. The cherry-picking visitors’ most demanding tastes will be satisfied experiencing the latest technologies and state-of-the-art inspection and sorting machinery live in action.

They will attend special workshop sessions and consult Dimac experts in the choice of suitable application solutions, discussing about the latest 4.0 newness, e.g. Dimac integrated ecosystem of apps and cloud services – or the upgraded software packages, e.g. New MCVx optical system, the predictive forming control tool Volume Plus, the program to manage the machines on the Net MCVx Remote.

They will attend special workshop sessions and consult Dimac experts in the choice of suitable application solutions, discussing about the latest 4.0 newness, e.g. Dimac integrated ecosystem of apps and cloud services – or the upgraded software packages, e.g. New MCVx optical system, the predictive forming control tool Volume Plus, the program to manage the machines on the Net MCVx Remote.

Dimac new stand will come as a surprise, re-designed so that attendees are welcomed in a friendly meeting space that stimulates a strong turnout of proposals and new projects. WIRE 2018 will be the occasion to view breakthrough equipment that will be launched to the market soon, expanding Dimac product range: SPC-ROBOT, conceived to significantly shorten the quality process chain.

Freshness and variety are important ingredients spicing Dimac creative engineering approach. The consistent commitment for high-end, Best-in-the-Business and smart solutions is mixed up with an attitude of openness allowing to establish trustworthy and loyalty partnerships with the customers.

Actually, this cookery keeps the Italian company’s in a very good shape: improving its facilities, investing for further growth also with important infrastructure projects, e.g. the construction of the new headquarter. Massimo concludes, “We expect to confirm the success of the previous editions, exchanging expertise and building new business partnerships.”

(Booth 15H11; Hall 15)

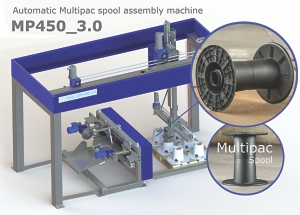

Windak Group/ Axjo AB

MULTIPAC spools – Space and Money Saving Solution from Windak / Axjo Co-venture – NEW Innovations at wire 2018

At the show will be Axjo’s MultiPac spools and Windak’s automatic spool assembly machine MP450_3.0.

Development of new logistics-enhancing products was one of the main goals for Windak and Axjo collaboration during the year of 2017. Together with its co-partner Axjo, which is premier supplier of spools in Europe, we invented a great money-space saving solution for spooling of wire and cable.

Development of new logistics-enhancing products was one of the main goals for Windak and Axjo collaboration during the year of 2017. Together with its co-partner Axjo, which is premier supplier of spools in Europe, we invented a great money-space saving solution for spooling of wire and cable.

“For a number of years, we have seen and heard from our customers about the huge interest in saving space during transport. This has resulted in a whole series of innovative products and solutions,” said Axjo AB.

Axjo’s MultiPac spool is divided in the middle and has a slightly conical barrel. This allows each half of the spool to be stacked; this means that up to three times as many spools can be loaded on a trailer, which is good for the environment.

Windak’s NEW MultiPac automatic spool assembly machine MP450_3.0 produces 3 spools per minute and is suitable for spools of 400 & 600 mm in diameter and 300mm & 450 mm in width. The MP450_3.0 automatically assembles the MultiPac spools and loads them into the spooler, thus eliminating manual depalletizing and loading of spools into the machine. In combination with one of our AR series spooling machines you can get high performance, European quality and production efficiency all in one line.

Customers will:

- Save 1/3 on freight expenses

- Have 3 times more spools loaded on the truck

- Save 1/3 on personnel costs

- Need 1/3 less storage space at your facility

- Have an environmentally friendly solution

The NEW MultiPac spools and spool assembly machine MP450_3.0 will be presented at the Wire 2018 trade fair in Düsseldorf, together with Windak’s AR18 Spooling machine. The Auto Reeler AR18 is a dual head fully automatic reeler developed for automatic packaging of cable and wire products on reels between 216 – 460 mm (8.5”-18”) in over all diameter. It can be run both, in line (with an extruder) and offline (with a driven Payoffor Flyer) and loads and unloads the reels automatically. Includes stretch wrapping of the reel to contain the cut end. AR18 Spoolermakesupto 2.5 spoolsperminute.

(Windak Group – Booth 9B42; Axjo AB – Booth 12A56)

Gurfil

Gurfil to Showcase its Foil, Film, Tape and Machinery Products at wire 2018

The company serves throughout the world with its Foil – Film – Tape products (such as ALU/PET, Cu/PET, PET film, mica tape, fiberglass tape, non woven, pp foam tape, identification tape etc.) together with machinery.

Gurfil is a well-known manufacturer of raw materials and machinery for the cable industry established in Istanbul, Turkey in 1981. Since company’s foundation, the company is proud to serve its customers throughout the world with its Foil – Film – Tape products (such as ALU/PET, Cu/PET, PET film, mica tape, fiberglass tape, non woven, pp foam tape, identification tape etc.) together with machinery, offering commissioning, after-sales technical service and all spare parts from its warehouse with professional service team.

Gurfil is a well-known manufacturer of raw materials and machinery for the cable industry established in Istanbul, Turkey in 1981. Since company’s foundation, the company is proud to serve its customers throughout the world with its Foil – Film – Tape products (such as ALU/PET, Cu/PET, PET film, mica tape, fiberglass tape, non woven, pp foam tape, identification tape etc.) together with machinery, offering commissioning, after-sales technical service and all spare parts from its warehouse with professional service team.

For Gurfil, 2017 has become a year full of achievements and challenges. It began the year with installing and launching one of the latest spooling technology machines. That allowed the company to significantly increase the production capacity meeting all necessary safety and quality requirements to the cable raw materials.

Greater length of material is on the advantages of spool winded cable raw materials usage. A cable manufacturer can run its equipment for a longer period of time without having a stop, which means savingtime on changing the bobbins and minimizing the cable waist. Also spool winded materials has better and safer packaging for transportation.