A visit to HPL’s copper wire and cable manufacturing facility at Gharaunda, Haryana educated us about the series of complex technical operations performed to make this very essential product for power and data driven life. The tour also informed us why HPL shares a unique position in the market in terms of quality and safety of cables.

Copper wires and cables are mainstays of our electric power driven life and, whether in home or industry, one can but little imagine an engineering system run without such wires and cables. However, how often have we asked about how these copper wires and cables are produced? WCI recently got invited on a brief press tour of a most modern copper wire and cable manufacturing facility to witness a firsthand account of copper wire and cable manufacturing process. The facility in this case was HPL Electric & Power Limited’s Gharaunda unit in Haryana. Although HPL stands among few notable players in domestic/housing wire segment, it has extended its range to include other niche and specialty cabling requirements, including various single / multi-core sheathed/ unsheathed cables.

The tour made us understand not only that copper wire and cable manufacturing is a complex process, but also that myriads of engineering expertise and precision machining are involved in making a product that meets original manufacturing specifications and tolerances. On this guided tour, interspersed with brief interviews with managers, experts, and supervisors, the high capital cost of machinery and factory building also became evident. HPL’s factory layout, designs, and smooth operations made it clear that cable-making business is demanding one and also why many companies are struggling.

“Copper cable making is a complex process is not perceived when a general user holds such a cable in his hand. There are a series of complex and technical processes involved in the manufacturing of quality cable, which is safe and standard. If you see the manufacturing set-up what we have put up, it’s simply cutting-edge and one of the best out there. We currently have two fine wire drawing machines from Niehoff with other machines and tools acquired from the top suppliers of the world. Overall factory, its layout and machines we use here are all world class. HPL Cables is an independent company within a company and we can compete with anybody in this category,” says Mr. Gautam Seth, Jt. Managing Director, HPL Electric & Power Limited. “I am sure you will be able to understand what I am saying when you will have taken a tour of our Gharaunda facility,” he adds.

“Copper cable making is a complex process is not perceived when a general user holds such a cable in his hand. There are a series of complex and technical processes involved in the manufacturing of quality cable, which is safe and standard. If you see the manufacturing set-up what we have put up, it’s simply cutting-edge and one of the best out there. We currently have two fine wire drawing machines from Niehoff with other machines and tools acquired from the top suppliers of the world. Overall factory, its layout and machines we use here are all world class. HPL Cables is an independent company within a company and we can compete with anybody in this category,” says Mr. Gautam Seth, Jt. Managing Director, HPL Electric & Power Limited. “I am sure you will be able to understand what I am saying when you will have taken a tour of our Gharaunda facility,” he adds.

Manufacturing Process at HPL, Gharaunda

Mr. Seth was right as it was amply evident that producing a copper cable is filled with innumerable nuances as to making and testing at various stages to meet the stringent quality parameters. Rod breakdown and wire drawing together constitute the first step, where copper rods are reduced to copper wire. “The  only way to achieve greater productivity and precision in wire manufacturing is with the simultaneous drawing of a number of wires together. Copper rods are shifted to machine by overhead crane. Therefore, we have procured two multiwire drawing machines from Niehoff, Germany, out of which one draws 16 wires and the other one 24 wires at a time. Moreover, we have two rod breakdown machines from Tomer Engineering, which breaks down 8mm wire rod to 1.6mm diameter rods, which then goes to multiwire drawing machines,” says Mr. Anil Kumar Singh, DGM, Production, HPL (Gharaunda facility).

only way to achieve greater productivity and precision in wire manufacturing is with the simultaneous drawing of a number of wires together. Copper rods are shifted to machine by overhead crane. Therefore, we have procured two multiwire drawing machines from Niehoff, Germany, out of which one draws 16 wires and the other one 24 wires at a time. Moreover, we have two rod breakdown machines from Tomer Engineering, which breaks down 8mm wire rod to 1.6mm diameter rods, which then goes to multiwire drawing machines,” says Mr. Anil Kumar Singh, DGM, Production, HPL (Gharaunda facility).

During the wire drawing process, the copper rod is pulled through a series of natural diamond & Polycrystalline dies, which gradually decrease in size. The rod and dies are flooded with a coolant and a synthetic lubricant to increase the life of the dies and keep the copper wire from overheating. Niehoff’s two multidrawing lines with 16 and 24 wire outputs have maximum line speeds 31.5 m/s and 36 m/s respectively. For both 16-wire and 24-wire Niehoff machines, the diameter of finished wire ranges from 1.60 mm-0.20 mm. So when such need arises, both the lines can run simultaneously to draw as much as 16 wires & 24 wires individual as well as separately in 02 take ups respectively .

During the wire drawing process, the copper rod is pulled through a series of natural diamond & Polycrystalline dies, which gradually decrease in size. The rod and dies are flooded with a coolant and a synthetic lubricant to increase the life of the dies and keep the copper wire from overheating. Niehoff’s two multidrawing lines with 16 and 24 wire outputs have maximum line speeds 31.5 m/s and 36 m/s respectively. For both 16-wire and 24-wire Niehoff machines, the diameter of finished wire ranges from 1.60 mm-0.20 mm. So when such need arises, both the lines can run simultaneously to draw as much as 16 wires & 24 wires individual as well as separately in 02 take ups respectively .

After wire drawing, the wire is extremely brittle and can easily be fractured if flexed. Since finished copper wire must be flexible, the wire is softened, or annealed, at this point. Annealing is accomplished by passing a large electrical current through the wire for a fraction of a second, raising its temperature briefly to 1000OF. To prevent oxidation of the wire, this step is performed in water. The water bath also cools and cleans the wire in preparation for the insulating step.

HPL’s logic to go for Neihoff’s multidrawing line seems to stem from the fact that these multidrawing lines have in-built powerful annealers. “The USP of the machine is its being a multi-function machine, i.e. drawing multiple wires at a time along with annealing, which is necessary to increase wire’s mechanical and physical properties,” notes Mr. Singh. “The single wire drawing machines may have many limitations and may require you to perform various operations separately resulting in time, volume, and quality loss. These multiwire drawing lines seem to have taken those constraints into consideration and yields wire with diametric precision, wherein one is spared from further drawing of wires in the insulate and extrusion area to meet the specifications. You get the coils of wires ready to go directly to insulate and extrusion operations.”

The wire, now soft and flexible, is now ready for bunching operation, where HPL has lined up over 10 automatic, excellent bunchers, mostly from Niehoff again. Bunching of fine copper wires is necessary to give shape to loose wires, circular twisting of conductors, and lending a grip to the wire. “The bunchers help us in the pre-selection of the lay length. Moreover, the automatic setting of winding width during operation minimizes the risk of broken wires and provides the guarantee for perfect winding quality. Wires are bunched at a maximum speed up to 5/sec. with an output weight of 4 MT per day per buncher depending upon size. The lay is proper and the speed is good,” notes Mr. Singh.

The wire, now soft and flexible, is now ready for bunching operation, where HPL has lined up over 10 automatic, excellent bunchers, mostly from Niehoff again. Bunching of fine copper wires is necessary to give shape to loose wires, circular twisting of conductors, and lending a grip to the wire. “The bunchers help us in the pre-selection of the lay length. Moreover, the automatic setting of winding width during operation minimizes the risk of broken wires and provides the guarantee for perfect winding quality. Wires are bunched at a maximum speed up to 5/sec. with an output weight of 4 MT per day per buncher depending upon size. The lay is proper and the speed is good,” notes Mr. Singh.

Now when the coil of bunched copper wire is ready, it is transferred by suitable trolleys to the insulating or extrusion area of the plant and are fed into insulate line. At HPL, we witnessed seven high-speed, bi-color PVC extruders with control panels and other latest fittings. The bunched copper wire is passed through extruders, where either a single or double coating of plastic is applied. Specially formulated hard grade PVC pellets or XLPE/HDPE, with distinct color coding as per TEC, are fed into the cool rear section of the extruder; as they are pushed forward, they are heated until they melt. Exiting the extruder, the coated wire, now traveling at high speed up to 600 meter/minute, passes through another cooling trough and is coiled on takeup reels.

“We have seven PVC extruders, two from Supermac and five from SKM Engineering Works. In addition, we have one XLPE/PVC extruder from Sant Engineering. During manufacturing operation, wire/cable and insulation/sheath diameter are measured on line to avoid any failures, and the wire is tested for such electrical properties as capacitance and resistance. We have highly rated equipment for such testing in-built in the extruders like SIKORA’s on line diameter controller and spark tester, etc,” informs Mr. Singh.

“We have seven PVC extruders, two from Supermac and five from SKM Engineering Works. In addition, we have one XLPE/PVC extruder from Sant Engineering. During manufacturing operation, wire/cable and insulation/sheath diameter are measured on line to avoid any failures, and the wire is tested for such electrical properties as capacitance and resistance. We have highly rated equipment for such testing in-built in the extruders like SIKORA’s on line diameter controller and spark tester, etc,” informs Mr. Singh.

A single insulated conductor/cable can be an end product commonly known as hook up wire that may be used for low voltage, low current applications. HPL has a leading market share in this house wiring segment. These single insulated cables then can be twisted and stranded to form multi-core cable as the need may be; then comes the cabling and jacketing of such cables for extra safety and longevity. At HPL Gharaunda, there are two high-speed stranding cum laying machine from Niehoff doing the job with precision.

Described briefly, as they are here, these processes may sound simple, but given the range of products manufactured by HPL and the varying mechanical and electrical requirements for each, the jobs of the technicians operating the manufacturing equipment can be quite complicated. On the insulate line, for example, new operators go through an adequate training program that includes both classroom instruction and work experience on the plant floor. An on-the-job certification process follows.

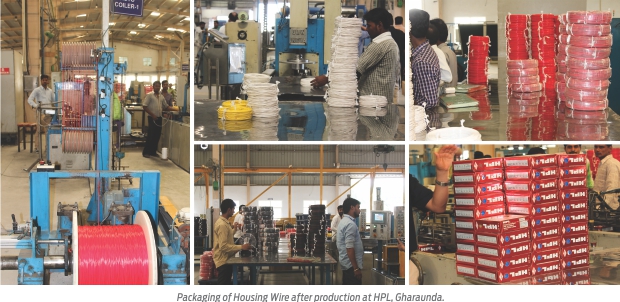

When the cable is finally made, the finished cable is wound onto metal or wooden reels and then transported to the final test facility. At the test facility, each cable is given a final test for physical consistency before electrical testing begins. Apart from regular electrical testing for current flow consistency, a high-voltage test is also performed, and all conductors are checked for electrical integrity.

Types of Cables Produced at HPL, Gharaunda

HPL major dedication in housing wires has given it a kind of unrivalled market position with over 10 percent of market share in housing wire, much because of a cutting edge manufacturing facility at Gharaunda. The existing capacity is 700-750 tonne in copper installed machines and the total capacity utilization is 400 tonne as of now. The facility has been designed in such a manner that expansion beyond 750 tonnes of copper may easily be executed after the full capacity utilization.

HPL today makes a range of domestic and industrial cables with a critical focus on fire-retardant and zero halogen. Going for a set of specialized cables was a logical extension of HPL’s already existing product portfolio. At extensive Gharaunda unit, HPL began manufacturing of specialty cables after installing proper technical setup at especially for the purpose.

Our team witnessed many completed orders of these specialty cables, which, apart from being weather-, gas-, oil-, and water-resistant, have the feature to perform at temperatures ranging from minus 40 degree Celsius to plus 750 degree Celsius. Many specialty cables here are designed to provide solutions for distortion free signaling and special bending radii.

HPL’s specialty cables portfolio now comprise of oil resistant battery cables, flat elevator cable(lift cable), DC solar cables UV resistant cable, wind power cable, instrumentation cable, fire alarm cable, LAN cable, fire survival cable, speaker cable, and CCTV cables. The specialty cables produced at HPL, Gharaunda target a host of industries and applications, right from automotive, realty, and non-conventional energy to control-instrumentation, data networking and domestic.

Asked on why HPL housing wire and specialty cable are witnessing such growing demand in the market, Mr. Singh says, “We use the best copper and PVC or insulating materials. Moreover, generally, no company is dedicated 100 percent to the housing wire cable, which gives us an edge over others; our focus therefore remains undiluted and quality checks unparalleled. You have already seen the manufacturing process, which is truly global and cutting-edge. We consider this section as important one among the wire ranges and treating it in a special way unlike the casual approach. Besides, our R&D department is strong, where we are doing the test even after getting the proper results of the product. We have a proper process of testing – from inception to the terminal.”

Solar Cable, a New Offering from HPL, Gharaunda

HPL has designed its innovative solar cable, which is going to be flexible, single-core cable with flexible electroplated tinned copper conductor insulated with special cross linked halogen free Elastomer. These solar cables will be low smoke zero halogen sheathed, UV and Ozone resistant. The cable has been duly designed and now under testing for TUV certification. “In India there are 3-4 such plants. The tests are special and process is not that simple; major R&D work is involved. As these types of plants have not gained much success in India, we increased the check points and enhanced the internal testing at every level in order to avoid any the chances of error,” informs Mr. Singh.

“Obviously, we can’t go into bulk production immediately; first we have to set-up and then look after the volume. Quality is what, which matters to us. The project is under process. It will just take couple of more months, and after getting license, we will start making it commercially. Internally, everything has been passed. Only TUV approval is awaited,” adds Mr. Singh.

On asked about the special technical specifications and requirements for producing a quality solar cable, Mr. D. P. Dimri, Deputy Manager (Q.A.), HPL (Gharaunda) says, “The conductor we use in solar cable is tinned. Normally, the copper we use in producing other cable is bare. The difference between solar cable and other cables the compound having special properties like XLPO- HFFR – cross likable halogen free fire retardant, RoHS with UV resistant and extremely expensive – almost 7-8 times costlier that the normal cable. This is the main reason why people find it difficult to enter into solar projects. Ultimately, people have to enter into this zone as solar cables in the coming years will be in demand by virtue of big push to renewable energy generation.”

On asked about the special technical specifications and requirements for producing a quality solar cable, Mr. D. P. Dimri, Deputy Manager (Q.A.), HPL (Gharaunda) says, “The conductor we use in solar cable is tinned. Normally, the copper we use in producing other cable is bare. The difference between solar cable and other cables the compound having special properties like XLPO- HFFR – cross likable halogen free fire retardant, RoHS with UV resistant and extremely expensive – almost 7-8 times costlier that the normal cable. This is the main reason why people find it difficult to enter into solar projects. Ultimately, people have to enter into this zone as solar cables in the coming years will be in demand by virtue of big push to renewable energy generation.”

Adding he says, “The biggest challenge in the production of solar cable is that the testing procedure is lengthy and time taking. It goes through a long testing period, where the cable is kept at 90 degree for approx. 7 months. There is a series of tests, which finally conclude the properties of the cable in terms of loss of mass, variation in tensile strength, elongation, etc. There are Damp Heat Test, test of resistance against acid and alkaline solutions, and other tests like ozone and UV resistance, etc. There is no inadequacy in the production from our side. We are in close contacts with TUV over clearance of HPL designed solar cable and we are in process to get TUV approval.”