Customers who use VNT nano-dies for drawing aluminum and alloys report excellent results in which the material strength is enhanced and in many cases the electrical resistance is reduced.

May 15, 2017

Ajex & Turner have come up with the new revolutionary Vitrified Nanocrystalline Technology which has completely changed the traditional way of wire drawing.The Prospects of Vitrified Nanotechnology will definitely put huge impact in near future and will save material and manufacturing costs for cable companies around the globe.

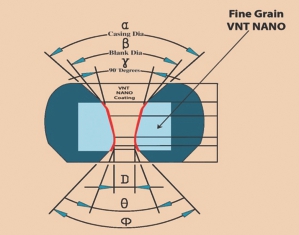

Ajex & Turner’s R&D team has developed state-of-the-art diamond coated dies called as VNT Nano. Even commonly same VNT nano-die can be used for compacting copper and aluminum if there is slight difference in the profile, not extreme.

Ajex & Turner’s R&D team has developed state-of-the-art diamond coated dies called as VNT Nano. Even commonly same VNT nano-die can be used for compacting copper and aluminum if there is slight difference in the profile, not extreme.

Customers who use VNT nano-dies for drawing aluminum and alloys report excellent results in which the material strength is enhanced and in many cases the electrical resistance is reduced.

Usages, Features, and Benefits:

- To draw copper-aluminum for stranding / compacting / multiwire / sector shape etc.

- To draw aluminum alloy wire / nickel silver wire / brass & tubes of any metal

- To draw stainless steel wire, high and low carbon steel wire up to 0.6%C, MIG/ CO2 wire or any hard / soft wire

- Lower friction – Better copper and aluminum utilization

- Better surface quality – high and bright surface finish

- Die range: 0.800 to 100mm possible

- Improvement of 2-3% in raw material utilization & better life than PCD and tungsten carbide

- 0% tolerance for entire working life for any metal

- No die re-polishing/re-cutting required for any metal

- The die will run for aluminum, copper compacting approx. 80000-100000 cable km, (If proper parameters maintained. The production ratio also depends on metal to metal through VNT nano dies)

- For aluminum / copper RBD process, VNT nano dies are better for continuous process with no metal loss & tolerance breakage or scratch on wire

- The prices are 10% to 50% lower than PCD dies (depends on bore diameter)

- Casing – stainless steel grade 304 to avoid rust

Why VNT NANO is better than TC & PCD for Drawing and Compacting:

FOR TC – While using tungsten carbide die for soft or hard material, there are chances of dust accumulation in the die and wire breakage and scratches on the conductor

FOR PCD – While using polycrystalline diamond die for soft and hard wire drawing purpose, above mentioned problems can be rectified, diameter can be controlled but variation is possible after a due course of time. But VNT nano maintains 0% tolerance throughout its working life, thus there is no need for re-polishing and re-grinding; moreover, VNT nano is economical in price than PCD with equivalent production.