Miltec has developed its own arc and microwave UV curing systems for optical fiber and many other industries. Additionally, the manufacturer has also patented an optical reflector system.

It has been more than 30 years since Miltec UV started in the ultraviolet (UV) business as a distributor of UV curing system parts and supplies. With a focus on quality and innovation, Miltec sources quality products from around the world and is a leading US-based manufacturer of microwave bulbs.

Miltec creates each of its bulbs from the highest quality materials. Every bulb is thoroughly examined and tested to ensure that it meets spectral output standards before being shipped around the globe.

Always innovating, Miltec not only developed its own arc and microwave UV curing systems for optical fiber and many other industries, it also patented an optical reflector system for optical fiber curing, created lamps with bulbs and reflectors that can be changed out in a matter of minutes, and most recently, created a way for Li-ion battery manufacturers to achieve significant savings on production using UV curing technology.

Going to the Xtrema for Fiber Optics

Specific to optical fiber, wire and cable, microwave-powered UV lamp systems are ideal, offering:

- Long-lasting bulbs with consistent UV output.

- Low IR heat output.

- Various bulb types (H, H+, D, and V) to tailor the UV spectral output to user-specific applications.

- End-to-end lamp placement for curing substrates of any cure length or width.

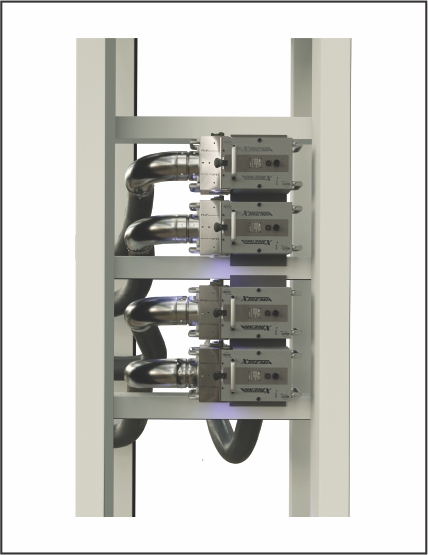

The Xtrema Eco UV system is the latest development in electrodeless UV lamp technology, which can be configured and optimised for the customer’s specific application. The Xtrema Eco lamp is a 10-inch UV lamp offered with reflector geometries to optimize how the UV light is delivered to the substrate.

Watch: Cable & Wire Fair Show Reel

For curing coating/ink on optical fiber, the compact curved reflector optimised for maximising the peak irradiance at the fiber is installed in the lamp. The peak irradiance that the Xtrema Eco delivers is higher than competitors’ higher-powered electrodeless systems at 2/3 of the electrical energy consumption, saving companies thousands of dollars per year in electrical costs.

Higher UV peak irradiance output will allow the user to cure faster for increased production speeds and improved physical cure properties. Additional benefits and features that the Xtrema Eco UV system offers are:

- Quick starting lamp eliminates the need for shutters.

- Easy to retrofit or replace existing microwave-powered UV equipment.

- Fast bulb and reflector changes (or cleaning) with Miltec’s patented “Quick Release” RF Screen will reduce maintenance time and machine downtime.

The Xtrema Eco power supply delivers 4000 Watt of power to the UV lamp and features two power settings at full and half power. The power supply is compact in size, easy to install, easy to control, and remote control inputs and outputs easily integrate controls of the lamps for any size production line.

Designed specifically for the optical fiber market, the Xtrema ECO Fibercure lamp utilises a patented and optimised reflector design that more sharply focuses the UV light rays at its target, which significantly increases the UV intensity at the fiber compared to the competitor’s higher-powered electrodeless UV lamps. The Eco Fiber lamp is the best choice for fiber producers targeting maximum fiber draw speed with the minimum number of UV lamps, minimum heat load to the fiber, and minimum energy consumption.

Building on the success of the Xtrema Eco, the new Miltec Xtrema Plus is a 10-inch electrodeless lamp, powered by a 6000 Watt power supply, uses the same patented reflector technology to focus the UV light. This system incorporates a user-friendly design for easy installation, operation, troubleshooting, and maintenance.

Also Read: India@75: The Making of a POWER-ful Nation

The Xtrema Plus UV lamp will produce significantly higher UV peak irradiance and UV energy compared to other competitive UV systems. The benefits of higher UV output are as follows:

- Faster cure speeds = higher production speeds

- Improved through-cure = improved adhesion between ink/coating and substrate

- Improved surface cure properties such as scratch resistance, stain resistance, chemical resistance, and more

- Ability to cure even the most optically dense inks/coatings when other lower output UV systems cannot

- Reduces the number of lamps or lamp rows required = less space consumed, less energy consumed, and lower operating costs

The Xtrema Plus UV system is perfectly suited for a wide variety of UV markets and applications, including optical fiber draw towers, colouring, ribbon cables, FRP/GRP, metal pipe/tube coating, and wide web converting.

The Xtrema Plus power supply is the engine that powers the UV lamp with 6000 Watt of pure power. The power supply is compact, easy to install and operate, and is designed to be extremely maintenance-friendly and is field serviceable resulting in lower operating costs.

Miltec’s innovations and contributions to UV technology have made them the source for quality systems and parts. With significant energy and operating savings through efficient design and easy maintenance features, companies will enjoy an attractive return on investment in new lines or upgraded technology for optical fiber draw, colouring, and FRP coating.