The tight concentricity allows wire insulators to meet the demands of today’s super thin-wall constructions.

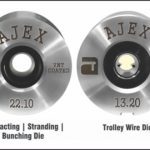

Ajex & Turner manufactures extrusion tips & dies in various shapes and sizes with alloy steel and special custom materials. It uses high-quality rust free steel with tested ideal OD & ID concentricity. The tight concentricity allows wire insulators to meet the demands of today’s super thin-wall constructions. These tools are made in alloy steel, carbide and diamond as per the customer’s requirement.

The extrusion dies can be tubing die, compression die or semi compression die. Ajex & Turner makes tip & die with a mirror polish and no sharp edges to ensure optimal insulation material flow and easy threading, smooth finish on cable.

The extrusion tip & die determines and strictly controls the shape and size of the insulating material. State-of-the-art technology of Ajex & Turner extrusion tools enable to maintain desired and even insulation thickness also saves the material and reduces the scrap. Super-hard diamond inserted in the die ensure long tool life even at high speed processes.

The end result is an insulated wire with uniform insulation thickness and precise conductor centering that provides the correct electrical characteristics in the finished product. While manufacturing tips & dies, the hole concentricity is controlled to use the following chemical composition to maintain the strength of the tool.

C-0.3 to 0.37 | SI – <0.4 | MN – 0.4 to 0.7 | CR – 1.5 to 1.8 | MO – 0.2 to 0.25 | NI – 0.9 to 1.15 | AL – 0.8 to 1.0 | P – <0.015 | S – <0.015 | CU – <0.15 |