“We have developed a 4000 mm drum twister line, for laying-up of cable of 3 core x 630 sq mm, having laid-up diameter of up to 125 mm… it is the biggest drum twister in India. Also, we have successfully commissioned a 3600 mm Milliken drum twister for the production of a 2500 sq mm conductor.”

In an exclusive conversation with Wire & Cable India, Mr. P.G. Sabu, CEO, Victory Plant and Machinery Pvt. Ltd., presents a run-through about the company, details about their manufacturing facility, the quality assurance strategies, the market-presence of the company and the future outlook on the wire and cable industry.

Wire & Cable India: Could you tell us a little bit about Victory Plant and Machinery Pvt. Ltd. and its business journey so far?

P.G. Sabu: Victory Plant and Machinery Pvt. Ltd. is recognized as a leading machine manufacturer for the wire and cable industry with a history of more than 28 years. Our manufacturing unit is located in Thane, Mumbai. We are renowned to provide excellence in all the aspects such as – product quality, delivery and customer support. Our continual development and unmatched customer service makes us one of the preferred suppliers for all the major cable manufacturers.

WCI: Tell us about your company’s product range, infrastructure and manufacturing capabilities. Do you have plans for expansion, technology up-gradation or investment in a new product line?

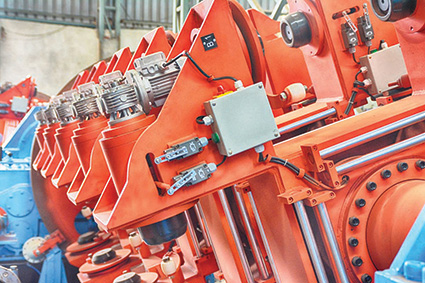

PGS: We are a specialist in rotating cable machinery, and our major products are – drum twister, rigid stranding machines, armoring machines, skip stranders, bow type laying-up machines, tubular stranders, planetary stranders, and high-speed taping machines.

Our factory area is 40000 sq ft with total in-house manufacturing units with the supporting infrastructure, machine tools, and equipment required for machine-building activities. Also, we are going to start a new production unit very soon.

“We are going to start a new production unit very soon…The development of new designs for multiple special cable lines is also underway.”

We have been continuously upgrading our facilities to improve the process quality, and to assist in faster machine building. The development of new designs for multiple special cable lines is also underway.

WCI: What new developments have taken place in your company?

PGS: A lot of enhancements in all the machines are continuously being carried out for improved production. Taping in the laying-up process has always been a bottleneck, and thus, we have developed high-speed taping machines to resolve the challenge.

We have developed planetary stranding machines for special-purpose cables with precision tension control mechanism and timer belt transmission instead of conventional gear systems. With this, the wear and tear can be avoided and drastic reductions in noise levels have been achieved. The machines with individual driven pay-off for stranding of 0.12 sq mm insulated cores have been developed.

WCI: What quality factors and R&D practices do you take into account before going for product development? How do you ensure that the precision of your products meets the global quality standards?

PGS: We take utmost care in each level of production – right from the sourcing of the material up to the machine-building process. Further, the testing of material before the usage, fit and tolerance of machine’s parts before assembly in addition to proper heat treatment, stress relieving procedures, checks, and quality testing is done at every stage of production. For new developments and critical applications, a prototype of critical components is first developed and tested and once it is found to be okay, the actual production is started.

Our vast industry-experience, proper product knowledge, and stringent quality control measures ensure that our products meet the global quality standards.

WCI: Tell us about the regions and markets you supply your products to. Does your market footprint extend to places outside India?

PGS: Victory has been a leading machine manufacturer in the country and we have also established our presence in the international markets. Our machines are supplied across India and are also exported to countries such as – UAE, South Africa, Nepal, Congo, Zambia, Mali and Bangladesh.

WCI: Victory has manufactured India’s biggest drum twister line and also the first Milliken conductor Drum Twister to be manufactured in India. Could you elaborate more about these projects?

PGS: We have developed a 4000 mm drum twister line, for laying-up of cable of 3 core x 630 sq mm, having laid-up diameter of up to 125 mm. It has a 26 cylinder caterpillar. We are proud to state that it is the biggest drum twister in India.

Also, we have successfully commissioned a 3600 mm Milliken drum twister for the production of 2500 sq mm conductor. The machine stands at par with its European counterparts. With us providing multiple lines, the quality and performance are at par with the imported lines and our clients have developed a high level of trust and confidence in our capabilities.

WCI: Could you tell us more about the automation division of your company and the services you provide to the wire and cable industry?

PGS: We have an in-house automation division wherein all the panels for our machines are built and tested. This assists us in delivering perfect products to our clients, within the stipulated time frame. On-site support for any of our machines can be easily provided online. Besides, we can provide upgradation and new panels for any of the existing as well as the new machines.

WCI: Considering the current scenario, what trends do you foresee in the wire and cable business across the world, especially in India, in the next 3-5 years?

PGS: The requirement for quality machines with high production capability is on the rise and highly automated machines are replacing the conventional machines. Thus, the solutions which are technologically advanced as well as reliable are the need of the hour.

While it is true that the outbreak of the COVID-19 pandemic has undoubtedly dealt a major setback to the wire and cable industry, however, with progressive policies and initiatives launched by the government, it is on a strong recovery path.