LS Cable & System has announced that the company would be the sole supplier of magnet wire for the drive motors (enamel wire) of the Hyundai IONIQ 5 and Kia EV6 electric vehicles.

March 22, 2021

LS Cable & System is the first in Korea to mass-produce magnet wires that can be used at 800V. Sales are estimated to reach more than KRW200 billion within 6 years.

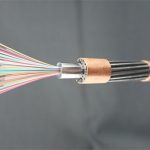

A magnet wire is a copper wire coated with a heavy insulation material. Such wire is wound around the drive motor in the form of coils and converts electric energy into mechanical energy. The company succeeded in using a high-performance insulation material to develop a high-voltage magnet wire with improved efficiency.

As the charging speed competition is intensifying in the electric vehicle industry, development of high-voltage parts supporting this is becoming more important. A company official said, “We expect that this supply will provide us with an opportunity to preempt the high-voltage electric vehicle wire market, which is still in its early stage.”

LS Cable & System believes that the global environment-friendly automotive magnet wire market will grow more than 6-fold by 2025, and it is reinforcing its marketing efforts and increasing investments with regard to global automakers.

“The drive motor and the battery are important enough to be called the two hearts of an electric vehicle,” said President & CEO, Myung Roe-Hyun, CEO of LS Cable & System. “We are certain that the wires and parts business, which serves as the blood vessels of the heart, will also grow rapidly, so we are fostering them as new growth engines.”

Read Wire & Cable India’s Interview with Mr. Hyun Ho Park, MD, LS Cable India Pvt. Ltd.

Since 2016, LS Cable & System has been supplying GM with the magnet wire (400V) for the drive motors of the company’s ‘Chevrolet Bolt EV.’ Currently, LS Cable & System is discussing development of the high-voltage magnet wires that are be used by all EVs to be produced by GM.