High Velocity Oxygen Fuel (HVOF) coating is a thermal spray coating process where oxygen and fuel gas are ignited in particular atmosphere. This process is used to improve or restore a component’s surface properties or dimensions, thus extending equipment’s life by significantly increasing its resistance to wear, corrosion and erosion.

Molten or semi-molten materials are sprayed out to the surface by mean of high temperature, high velocity gas stream, producing a dense spray coating which can be ground to a very high surface finish. The utilisation of the HVOF coating technique allows the application of coating materials such as metals, alloys and even ceramics to produce a coating of exceptional hardness, thus giving substantial resistance to corrosion and wear.

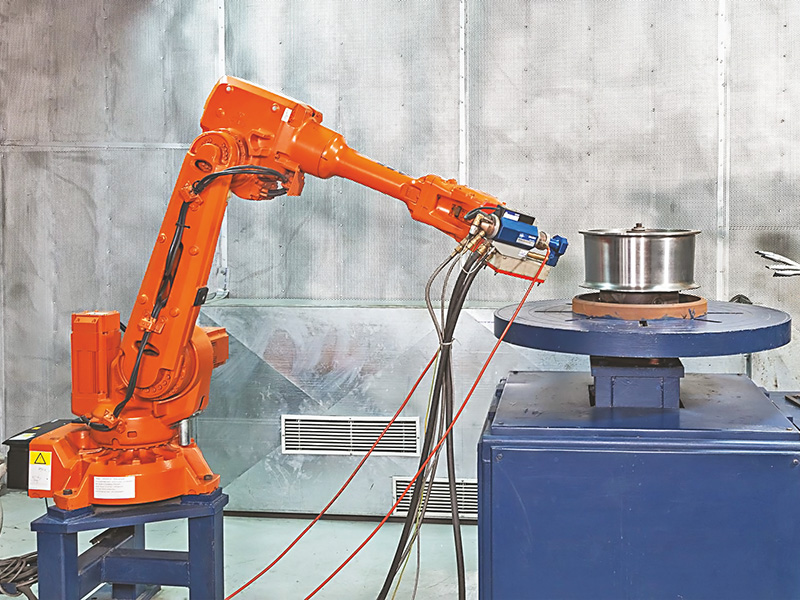

Assomac installed this system in-house for its wire drawing drums/cone rings and other components that help in giving a very long life to the components besides giving a very smooth surface finish of wire. The plant has been purchased from Sulzermetco and ABB (Robot)

The main advantage of HVOF coating

• Improves the performance of the component

• Enables the components to operate within harsh chemical environments.

• Reduces the cost of maintenance

• Enables the components to operate in higher/lower temperatures

• Improved efficiency of machine

• Improves life of mating components.

• Saves electrical energy.

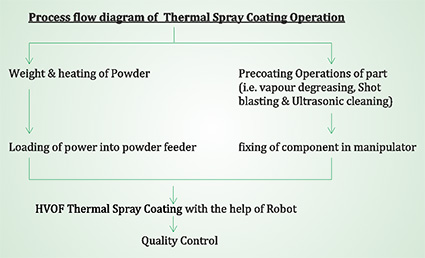

Process flow chart of HVOF

As with all thermal spray coating processes, HVOF coating material is heated and accelerated by a gas stream to a component’s surface to attain better properties. With the HVOF coating process, the gas stream is produced by mixing and igniting oxygen and fuel (gas or liquid) in a combustion chamber and allowing the high-pressure gas to accelerate through a thermal spray process.

Thermal spray process

The following process instructions are intended for use as a guide for coating of carbide powders using “HVOF” thermal spray coating. The instructions contain the list and description of production techniques and operation needs to accomplish the process of applying thermal spray coating on components as well as the list of main types of coating defect and their remedies.

In recent years, high velocity oxy fuel (HVOF) spraying has been considered an asset to the family of thermal spray processes, especially for the materials with melting point below 3000OC to 3300OC. It has proven successful since it shows advantages in density and bond strength making it attractive for many wear and corrosion resistance applications. Its high coating quality results from the use of a hot combustion and new high-speed gas jet for thermal spraying. These coatings have environmental advantages compared to chemically/electro-chemically formed coatings.

Tungsten carbide based powders are widely used in the HVOF spraying system. These are used to produce dense, high hardness and excellent wear resistance coatings generally to combat the erosion and corrosion occurring in hydro power plant and pumps wire industries. In applications where abrasive or corrosive wear resistance is of primary importance, wc-co (tungsten carbide) with and without nickel or chrome is used.

HVOF spraying does not have these limitations. HVOF thermal spray coating has a mechanical bond. The bond strength can be of high or 12000 psi, which is attained by the high kinetic energy of the particles.

Thermal spray coating is an attractive technique, as it offers a wide choice of materials and processes that have a reduced impact on the environment when compared to conventional plating processes.